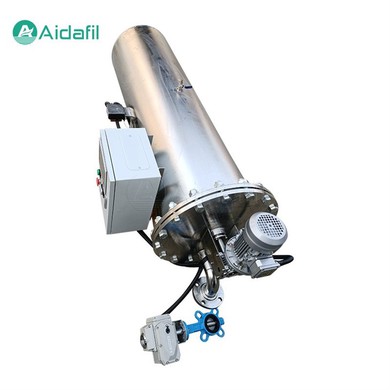

Heavy-Duty Horizontal Self Cleaning Filter

Product Details

The Heavy-Duty Horizontal Self Cleaning Filter functions to remove solid particles from the liquid, ensuring the safe operation of equipment and pipelines, and improving product quality and production efficiency. It is an efficient solid-liquid separation equipment widely used in water treatment, chemical industry, food, pharmaceutical industry, and other fields. Compared to traditional filtering equipment, horizontal fully automatic cleaning filters have advantages such as automatic cleaning, intelligent control, stable operation, and easy maintenance.

Here are some basic parameters

|

Single unit flow |

50-1200M3/H, larger flow can be realized by multiple single units in parallel |

|

Minimum working pressure |

0.2Mpa |

|

Maximum working pressure |

1.0/1.6/2.5/4.0Mpa |

|

Maximum operating temperature |

80°C |

|

Filtration accuracy |

130~3500 microns |

|

Control mode |

Differential pressure, timing or manual |

|

Cleaning time |

60s |

|

Cleaning mechanism speed |

14-20rpm |

|

Cleaning pressure loss |

0.01Mpa |

|

Control voltage |

AC 220V |

|

Rated operating voltage |

Three-phase, AC220V /380V, 50HZ |

I. Structure

The Heavy-Duty Horizontal Self Cleaning Filter mainly consists of the filter housing, driving device, control system, cleaning system, filter screen, and other parts.

(1) Filter Housing: It is used to accommodate the liquid and filter screen, and is usually made of corrosion-resistant and high-strength materials such as stainless steel, carbon steel lined with plastic, etc.

(2) Driving Device: It is used to drive the movement of the filter housing for automatic cleaning. The driving devices can be motors, pneumatic or hydraulic drives.

(3) Control System: It is used to monitor the operating status of the filter, including differential pressure alarm and cleaning control.

(4) Cleaning System: It includes cleaning water pumps, cleaning nozzles, cleaning pipelines, etc., used for cleaning the filter screen.

(5) Filter Screen: It is used to capture solid particles and is usually made of metal mesh, polytetrafluoroethylene (PTFE) or other materials.

II. Working Principle

The working principle of the Heavy-Duty Horizontal Self Cleaning Filter is shown in the following diagram:

The liquid enters the filter from the inlet and, after passing through the filter screen, the solid particles are captured by the screen while the clean liquid flows out through the screen, obtaining filtered liquid. As the filtration progresses, more and more solid particles are caught on the filter screen, and the internal differential pressure of the filter gradually increases. When the differential pressure reaches the set alarm value, the control system activates the cleaning device, drives the filter housing to move, and washes away the solid particles on the filter screen. After cleaning, the filter screen can continue to be used, and the entire filter realizes automatic cleaning and continuous operation.

III. Performance Features

1. Automatic Cleaning: The filter automatically starts the cleaning device when the pressure difference reaches the set value, without manual intervention, realizing unattended operation.

2. Intelligent Control: Advanced control systems are used to achieve automation of filtration, cleaning, and sludge discharge processes, improving production efficiency.

3. Stable Operation: The filter is manufactured using high-quality materials and advanced processes, featuring low vibration, low noise, and high reliability during operation.

4. Easy Maintenance: The structure of the filter is simple, and the cleaning is convenient. The filter screen can be replaced, and the maintenance cost is low.

5. High Filtration Efficiency: The filter screen is made of high-quality materials, which have a strong ability to capture solid particles, achieving a filtration efficiency of over 99%.

6. Strong Adaptability: The filter can be applied to the filtration of various corrosive media and temperature liquids, meeting the needs of different industries.

IV. Application Fields

The Heavy-Duty Horizontal Self Cleaning Filter is widely used in the following fields:

1. Water Treatment: Urban water supply, sewage treatment, industrial circulating water treatment, etc.

2. Chemical Industry: Petroleum, chemical, pharmaceutical, food industries, and other liquid filtration.

3. Energy: Thermal power, nuclear power, hydropower, and other energy industries' medium filtration.

4. Food: Beverage, dairy products, condiments, and other industries' liquid filtration.

5. Pharmaceutical Industry: Liquid filtration in the pharmaceutical industry, meeting GMP requirements.

6. Environmental Protection: Industrial wastewater, sludge treatment, and other environmental protection fields' liquid filtration.

V. Factors to Consider When Choosing

When selecting a horizontal self cleaning filter, consider the following factors:

1. Water Flow Rate: Choose a filter model that matches the required flow rate.

2. System Pipeline Pressure: Ensure that the filter can withstand the working pressure of the system.

3. Filtering Precision Requirements: Select the appropriate filter screen precision based on water quality requirements and downstream equipment needs.

4. Suspension Concentration: Water with high impurity concentration may require more frequent cleaning.

FAQ

1. Q: What is the function of a filter?

A: The main function of a filter is to remove solid particles, impurities, and harmful substances from liquids or gases, in order to achieve purification, clarification, and protection of equipment.

2. Q: How to choose a suitable filter?

A: When choosing a filter, factors such as the properties of the material being filtered (e.g., viscosity, temperature, corrosion), required filtration accuracy, processing capacity, operating pressure and medium, as well as the type, material, size, and installation method of the filter should be considered.

3. Q: What is the working principle of a filter?

A: The working principle of a filter mainly relies on physical screening, deep interception, absorption, or chemical reactions to remove impurities or harmful components from the material being filtered.

4. Q: How to maintain and care for a filter?

A: Maintenance of filters includes regular cleaning or replacement of filter elements, inspection of seals and fasteners, maintaining stable operating pressure, and avoiding overloading. Specific methods should be referenced from the filter's instruction manual and maintenance guides.

5. Q: What is the service life of a filter?

A: The service life of a filter depends on its working environment, processing volume, and filtration accuracy. Generally, when the filter's pressure drop reaches a certain value or the filtration effect decreases significantly, it needs to be replaced or cleaned.

6. Q: What should be paid attention to during filter installation?

A: During filter installation, attention should be paid to the directionality, ensuring that the fluid enters and exits from the correct ports. Also, the piping system should be cleaned before installation, and the filter should be securely fastened and sealed as required by the instructions.

7. Q: What is the replacement cycle for filters?

A: The replacement cycle for filters depends on their working conditions and filtration requirements, and is usually indicated by pressure difference indicators or timers. When the filter's pressure drop reaches the set value or the filtration effect decreases, it should be replaced in a timely manner.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: heavy-duty horizontal self cleaning filter, China, factory, price, buy, industrial oil filter in lubricating, Oil Separator, good filtrating oil separator air, 100 micron hydraulic oil filter element, large volume carbon steel bag filter housing, ford hydraulic oil filtration