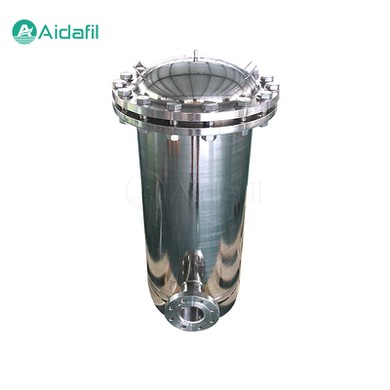

High-Performance Sanitary Bag Filter

Product Details

The high-performance sanitary bag filter makes the liquid to be filtered flow in from the inlet of the equipment, and the impurity particles in the liquid are intercepted by the interception of the filter bag, while the clean liquid is discharged from the outlet.

Structure

The high-performance sanitary bag filter is mainly composed of the following parts:

1. Filter cylinder

The cylinder is usually made of stainless steel or carbon steel, which has good corrosion resistance and pressure resistance. The cylinder is equipped with a multi-layer support net basket for fixing and supporting the filter bag.

2. Upper cover

The upper cover is used to close the cylinder to form a closed filter space. The upper cover is usually flanged or threaded to the cylinder to ensure a firm connection.

3. Quick opening device

The quick opening device is located between the upper cover and the cylinder body, which can quickly remove the upper cover, which is convenient for changing the filter bag and cleaning the cylinder body. This design greatly improves maintenance efficiency and saves time and labor costs.

4. Support the net basket

The support net basket is a bracket for placing the filter bag, usually made of wire mesh. The net basket has a certain strength and stiffness, which can effectively support the filter bag and prevent the filter bag from being deformed or damaged during the filtration process.

5. Filter bag

The filter bag is the core component of the bag filter, made of special filter material, with excellent filtration performance. The filter bag is installed in the supporting net basket, and the filtration function is realized through the seal between the upper cover and the cylinder.

Parameters

|

Flange standard |

HG, GB, SH, HGJ, J8, ANSI, JIS |

|

Connections |

Thread, Flange, Clamp |

|

Drain outlet specification |

1/4 |

|

Filtering precision |

0.5 - 800 μm |

|

Design pressure |

0.6 - 1.0 Mpa |

|

Design temperature |

90°C for PP filter bag, 130°C for PE filter bag, 240°C for PTFE filter bag |

|

Surface treatment |

Sand blasting, polishing |

|

Housing material |

20#, 304, 316L, 2205/2507, titanium |

|

Sealing gasket material |

Silica gel, NBR, PTFE |

|

Filter bag material |

Polyester, polypropylene, nylon, PTFE, glass fiber |

|

Model |

Max flow |

Nominal diameter |

Volume |

Filtering area |

D |

D2 |

H1 |

H2 |

H3 |

|

ADB-1/1 |

15 |

1 - 4 |

8 |

0.2 |

219 |

170 |

500 |

546 |

646 |

|

ADB-1/2 |

30 |

1 - 4 |

17.5 |

0.45 |

219 |

170 |

700 |

886 |

986 |

|

ADB-1/3 |

3.5 |

3/4 - 2 |

2.5 |

0.05 |

114 |

95 |

500 |

296 |

383 |

|

ADB-1/4 |

7.5 |

3/4 - 2 |

4 |

0.1 |

114 |

95 |

350 |

446 |

533 |

Product Features

1. Small chance of side leakage of filter bag

The filtration quality is effectively guaranteed, without the addition of any resin or adhesive, and without secondary pollution.

2. Pressure resistance

Bag filtration can handle higher working pressure, with small pressure loss, low operating costs, and significant energy-saving effects.

3. High filtration accuracy

The filtration accuracy of the filter bag has been continuously improved, reaching 0.5 μm, meeting the requirements of small-precision filtration.

4. Large filtration capacity

Bag filtration has large processing capacity, small size and large pollution capacity.

5. Easy and fast replacement

Based on the working principle and structure of the bag filter system, it is convenient and fast to replace the filter bag, saving labor and time.

6. Washable

The filter bag can be used repeatedly after cleaning, saving costs.

7. Wide range of applications

Bag filtration has a wide range of applications, flexible use, and various installation methods.

8. Safe and stable

Safe and stable sealing ring design, filtration efficiency can reach more than 99%.

9. Corrosion resistance

The part in contact with the liquid is all made of stable stainless steel, which has anti-corrosion effect on a variety of liquids.

10. Sanitary grade

Strictly control the selection of filter bag materials to meet hygienic requirements.

Application Fields

Due to its efficient and accurate filtration performance, the high-performance sanitary bag filter is widely used in many industries. For example:

1. Food and beverage industry

Used for pretreatment and end point filtration of products such as water, juice and alcohol to ensure product quality and taste.

2. Pharmaceutical industry

Used for the purification of raw material water, production water, preparation water, etc., in line with GMP standards.

3. Chemical industry

Used for the refining and recycling of various chemical raw materials, intermediates and products to improve product purity and yield.

4. Petroleum industry

Used in crude oil dehydration, refined oil refining, etc., to reduce production costs and improve product quality.

5. Electric power industry

Used for the purification of boiler feed water, cooling water, etc., to ensure the safe operation of equipment.

6. Environmental protection industry

Used in wastewater treatment, waste gas treatment, etc., to reduce pollutant emissions and protect the environment.

FAQ

1. Q: What is the function of a filter?

A: The main function of a filter is to remove solid particles, impurities, and harmful substances from liquids or gases, in order to achieve purification, clarification, and protection of equipment.

2. Q: How to choose a suitable filter?

A: When choosing a filter, factors such as the properties of the material being filtered (e.g., viscosity, temperature, corrosion), required filtration accuracy, processing capacity, operating pressure and medium, as well as the type, material, size, and installation method of the filter should be considered.

3. Q: What is the working principle of a filter?

A: The working principle of a filter mainly relies on physical screening, deep interception, absorption, or chemical reactions to remove impurities or harmful components from the material being filtered.

4. Q: How to maintain and care for a filter?

A: Maintenance of filters includes regular cleaning or replacement of filter elements, inspection of seals and fasteners, maintaining stable operating pressure, and avoiding overloading. Specific methods should be referenced from the filter's instruction manual and maintenance guides.

5. Q: What is the service life of a filter?

A: The service life of a filter depends on its working environment, processing volume, and filtration accuracy. Generally, when the filter's pressure drop reaches a certain value or the filtration effect decreases significantly, it needs to be replaced or cleaned.

6. Q: What should be paid attention to during filter installation?

A: During filter installation, attention should be paid to the directionality, ensuring that the fluid enters and exits from the correct ports. Also, the piping system should be cleaned before installation, and the filter should be securely fastened and sealed as required by the instructions.

7. Q: What is the replacement cycle for filters?

A: The replacement cycle for filters depends on their working conditions and filtration requirements, and is usually indicated by pressure difference indicators or timers. When the filter's pressure drop reaches the set value or the filtration effect decreases, it should be replaced in a timely manner.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: high-performance sanitary bag filter, China, factory, price, buy, 3um inline filter element, high filtration efficiency duplex basket strainer, Automatic Self Cleaning Filter, high flow rate gas filter element, compressed air filter element against oil vapor, 8mm wire wedge wire filter