Durable Standard 5-Layer Sintered Wire Mesh

Product Details

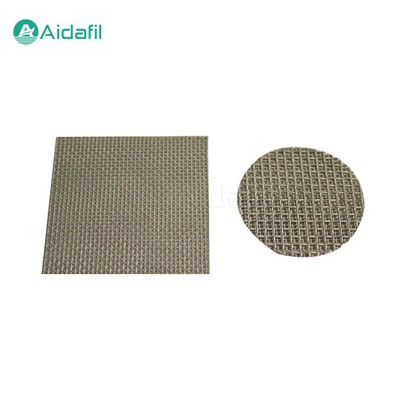

The durable standard 5-layer sintered wire mesh is a high-performance filter material made of five-layer stainless steel wire mesh superimposed by vacuum sintering technology. It is composed of a protective layer, a control layer (filter layer), a distribution layer, and two reinforcement layers. This multi-layer structure design not only enhances its mechanical strength and pressure resistance, but also enables precise filtration results. Each layer has its own unique function and works together to achieve the best filtration effect.

Manufacturing process

The manufacturing process of the 5-layer sintered wire mesh involves stacking five layers of stainless steel wire mesh together according to a specific structure, and then undergoing high-temperature vacuum sintering treatment. This process makes a strong connection between the layers at the microscopic level, thus ensuring the high overall rigidity and stability of the entire network.

Filtration accuracy

The durable standard 5-layer sintered wire mesh can provide filtration accuracy of 1 to 200 microns to meet the needs of different industrial applications. Due to its special structure and manufacturing process, the sintered mesh can maintain long-term stability in filtration accuracy and is not easily deformed due to pressure changes or long-term use.

Model parameters

|

Model number |

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

ADBSW1 |

1 |

6-7 |

180 |

5300-6000 |

|

ADBSW2 |

2 |

8-9 |

240 |

4300-5000 |

|

ADBSW5 |

5 |

11-13 |

260 |

3000-3700 |

|

ADBSW10 |

10 |

16-18 |

310 |

2700-3300 |

|

ADBSW15 |

15 |

24-26 |

350 |

2000-2600 |

|

ADBSW20 |

20 |

28-32 |

450 |

1800-2300 |

|

ADBSW25 |

25 |

34-36 |

620 |

1400-1900 |

|

ADBSW30 |

30 |

40-45 |

690 |

1200-1700 |

|

ADBSW40 |

40 |

50-55 |

720 |

1000-1500 |

|

ADBSW50 |

50 |

71-80 |

850 |

900-1200 |

|

ADBSW70 |

70 |

89-95 |

900 |

700-1100 |

|

ADBSW100 |

100 |

110-120 |

1080 |

650-1000 |

|

ADBSW150 |

150 |

180-200 |

2600 |

550-800 |

|

ADBSW200 |

200 |

260-280 |

2800 |

450-600 |

Characteristics

The durable standard 5-layer sintered wire mesh has a variety of characteristics, including high strength and rigidity, stable filtration accuracy, excellent corrosion and heat resistance, easy cleaning, and excellent ease of processing. The details are as follows:

1. High strength and rigidity

The standard 5-layer sintered mesh has extremely high mechanical strength and compressive strength due to its unique manufacturing process, which allows it to work stably in high-pressure environments without damage. This structure is also easy to cut, bend, punch and weld, allowing the material to be easily machined into various shapes and sizes to meet different application requirements.

2. Stable filtration accuracy

In the standard 5-layer sintered mesh design, the filter layer is located on the second layer, and the upper and lower protective layers are protected and supported to ensure that the particles are not embedded in the mesh during the filtration process, thus maintaining the long-term stability of the filtration accuracy. This design allows the sintered mesh to provide efficient filtration while maintaining low pressure loss.

3. Excellent corrosion resistance and heat resistance

The standard 5-layer sintered mesh is made of stainless steel SUS316L and SUS304, which not only provide good corrosion resistance, but also ensure that the sintered mesh can operate normally under extreme temperature conditions (from -200 °C to 480 °C), making it suitable for filtration tasks in acid-base environments.

4. Easy to clean

The structure of the standard 5-layer sintered mesh supports efficient countercurrent cleaning, which means easier and more economical maintenance and cleaning. By countercurrent cleaning, impurities trapped in the surface layer can be effectively removed, filtration performance can be restored, and service life can be extended.

5. Excellent ease of processing

The standard 5-layer sintered mesh is not only high in strength, but also easy to cut, bend, punch and weld, which provides great convenience for customizing filter elements of specific shapes and sizes. Users can process the sintered mesh into various forms of filter elements such as round, cylindrical, cone or corrugated according to specific application scenarios and equipment requirements. This flexibility allows the standard five-layer sintered mesh to adapt to the needs of changing industrial applications.

Application field

The durable standard 5-layer sintered wire mesh is widely used in petrochemical, metallurgical machinery, energy and environmental protection, textile power, aerospace and medicine industries. Its excellent filtration performance and reliable physical characteristics make it an indispensable filter material in these fields.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: durable standard 5-layer sintered wire mesh, China, factory, price, buy, high strength inline filter element, 50 m self cleaning screen filter, 15000 l min duplex basket strainer, 0 01um coalescing filter element, Air Filter Cartridge, compressor air oil separator in screw compressor