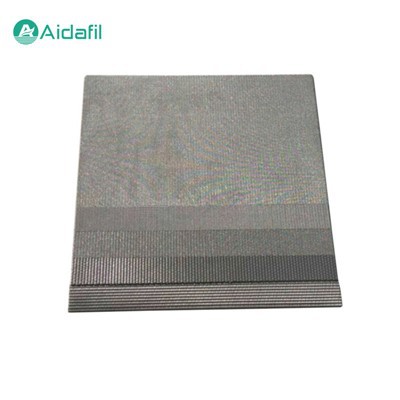

Square-Hole Metal Fiber Sintered Mesh

Product Details

The square-hole metal fiber sintered mesh is a sintered mesh made by sintering multiple layers of flat woven square hole mesh together. Due to the high porosity of the square hole mesh, the sintered mesh has the characteristics of high permeability, low resistance and large flow rate.

The standard dimensions are 500 × 1000mm, 600 × 1200mm, and 1000 × 1200mm. The standard materials are SUS316 and 304. The standard thickness is 1.7mm.

Characteristics

1. Good strength. The square-hole metal fiber sintered mesh has good stability, with extremely high mechanical strength and compressive strength.

2. Easy to clean. Due to the use of surface filter material, it is easy to clean and is especially suitable for backwashing.

3. Easy to process. It is suitable for cutting, bending, stamping, stretching, welding and other processing technologies.

4. High temperature resistance. It can withstand high temperatures of 480 °C.

5. Corrosion resistance. Due to the use of SUS316L and 304 materials, it has strong corrosion resistance.

6. Filtration accuracy. The filtration accuracy ranges from 1μm to 200μm, providing reliable filtration performance.

7. High porosity, uniform pore distribution and large filtration flow.

Model parameters

|

Model number |

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

ADBSW1 |

1 |

6-7 |

180 |

5300-6000 |

|

ADBSW2 |

2 |

8-9 |

240 |

4300-5000 |

|

ADBSW5 |

5 |

11-13 |

260 |

3000-3700 |

|

ADBSW10 |

10 |

16-18 |

310 |

2700-3300 |

|

ADBSW15 |

15 |

24-26 |

350 |

2000-2600 |

|

ADBSW20 |

20 |

28-32 |

450 |

1800-2300 |

|

ADBSW25 |

25 |

34-36 |

620 |

1400-1900 |

|

ADBSW30 |

30 |

40-45 |

690 |

1200-1700 |

|

ADBSW40 |

40 |

50-55 |

720 |

1000-1500 |

|

ADBSW50 |

50 |

71-80 |

850 |

900-1200 |

|

ADBSW70 |

70 |

89-95 |

900 |

700-1100 |

|

ADBSW100 |

100 |

110-120 |

1080 |

650-1000 |

|

ADBSW150 |

150 |

180-200 |

2600 |

550-800 |

|

ADBSW200 |

200 |

260-280 |

2800 |

450-600 |

Application fields

The application fields of the square-hole metal fiber sintered mesh mainly include the following aspects:

1. Petrochemical industry. Used for oil filtration, catalyst recovery, etc.

2. Pharmaceutical industry. To filter impurities in liquid medicine, etc.

3. Food and beverage industry. Such as beverage, alcohol filtration clarification.

4. Environmental protection field. Used for sewage treatment, waste gas purification, etc.

5. Fine chemical industry. To filter various chemical reagents.

6. Automotive industry. Such as engine oil filtration, etc.

7. Chemical fiber industry. To filter spinning melt, etc.

8. Electronics industry. For filtration in high-purity water preparation, etc.

9. Powder metallurgy industry. Used for powder classification and filtration.

10. Aerospace field. Filtration treatment of certain special fluids.

Fabrication process

The fabrication process of the square-hole metal fiber sintered mesh mainly includes the following steps:

First, select the appropriate wire material. The wire is woven into a metal mesh with a square hole structure. Then, the multi-layer metal mesh is superimposed and placed together. Next, the sintering process is carried out through a high-temperature sintering furnace. Under the action of high temperature, the metal wires are fused and connected to each other to form a whole sintered structure. After sintering, some subsequent processing processing may also be required, such as shaping, cutting, etc., to meet the specific size and shape requirements. The entire production process requires strict control of parameters such as temperature and pressure to ensure that the quality and performance of the sintered mesh meet the standards.

Influence of pore size distribution on filtration performance

The square-hole metal fiber sintered mesh boasts a uniform pore size distribution. The pore size distribution has the following important effects on the filtration performance:

1. Filtration accuracy

A uniform and appropriate pore size distribution ensures effective interception of particles in a specific particle size range, thus determining the accuracy level of filtration. If the pore size distribution is uneven, some particles may be easily penetrated or large particles may "slip through the net", reducing the filtration effect.

2. Filtration efficiency

Reasonable pore size distribution can capture impurities more efficiently when the fluid passes through, and improve the filtration efficiency. If the pore size distribution is unreasonable, it may cause the fluid resistance to increase and the efficiency to decrease, or the filtration may not be complete.

3. Pressure loss

A uniform pore size helps fluids pass through smoothly, reducing local resistance caused by uneven pore sizes, thereby reducing pressure loss and making the filtration process more energy-efficient.

4. Service life

Good pore size distribution can make the filtration process more stable, reduce uneven wear on the mesh, and help prolong the service life of the sintered mesh. If the pore size distribution is not good, it may lead to premature damage to some parts and affect the overall service life.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: square-hole metal fiber sintered mesh, China, factory, price, buy, easy clean stainless steel sintered wire mesh, pleated media compressor air oil separator, high pressure lubricating oil filter element, sintered wire mesh for punching, Wedge Wire Filter, 2 microns sintered filter disc