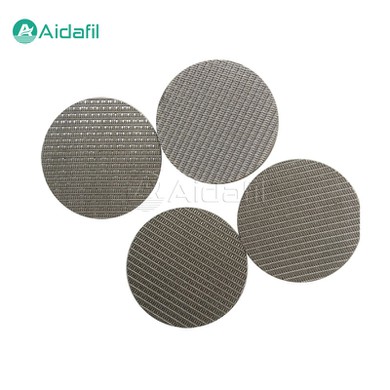

Round Stainless Steel Sintered Mesh Filter Disc

Product Details

The round stainless steel sintered mesh filter disc is a filter material made by folding and pressing multiple layers of stainless steel wire mesh in a specific order and process, and sintering at high temperature.

As a highly efficient filter material, the round stainless steel sintered mesh filter disc plays a vital role in many industrial fields. With its excellent performance and wide applicability, it provides strong support for achieving fine filtration, improving production efficiency and ensuring product quality.

Performance characteristics

1. High filtration accuracy

Due to its multi-layer structure and fine mesh, it can effectively filter out tiny particles and impurities, and the filtration accuracy can reach the micron level.

2. High strength

After high-temperature sintering, the stainless steel wires are tightly combined, so that the filter disc has high strength and compressive resistance, and can withstand greater working pressure.

3. Good corrosion resistance

The selection of high-quality stainless steel materials enables it to work stably in corrosive media such as acids, alkalis, and salts, and is not prone to corrosion and damage.

4. High temperature resistance

It can work for a long time in a high temperature environment, and the maximum working temperature can reach more than 800℃.

5. Easy to clean

The surface is smooth and not easy to clog. The attached impurities can be easily removed by backwashing or chemical cleaning to restore the filtration performance.

6. Long service life

Due to its excellent performance and sturdy structure, the round stainless steel sintered mesh filter disc has a long service life, reducing the replacement cost and maintenance frequency.

Parameters

|

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

1 |

6-7 |

180 |

5300-6000 |

|

2 |

8-9 |

240 |

4300-5000 |

|

5 |

11-13 |

260 |

3000-3700 |

|

10 |

16-18 |

310 |

2700-3300 |

|

15 |

24-26 |

350 |

2000-2600 |

|

20 |

28-32 |

450 |

1800-2300 |

|

25 |

34-36 |

620 |

1400-1900 |

|

30 |

40-45 |

690 |

1200-1700 |

|

40 |

50-55 |

720 |

1000-1500 |

|

50 |

71-80 |

850 |

900-1200 |

|

70 |

89-95 |

900 |

700-1100 |

|

100 |

110-120 |

1080 |

650-1000 |

|

150 |

180-200 |

2600 |

550-800 |

|

200 |

260-280 |

2800 |

450-600 |

Application fields

1. Petrochemical industry

In the process of petroleum refining and chemical production, it is used to filter crude oil, chemical raw materials, catalysts, etc., remove impurities and particulate matter, and ensure the smooth progress of the production process and product quality.

2. Pharmaceutical industry

Used for liquid filtration and sterilization filtration in the pharmaceutical process to ensure the purity and safety of drugs.

3. Food and beverage industry

Used to filter impurities and microorganisms in food raw materials and beverages to improve product quality and hygiene standards.

4. Electronics industry

In the process of electronic component manufacturing, filter tiny particles in gas and liquid to prevent pollution and damage to electronic products.

5. Environmental protection industry

Used in environmental protection equipment such as sewage treatment and exhaust gas purification to remove harmful substances and particulate matter and protect the environment.

6. Aerospace field

In the hydraulic system and fuel system of aerospace equipment, it plays a role of filtering and purification to ensure the normal operation of the equipment.

7. Automobile manufacturing industry

Used for oil filtration and fuel filtration of automobile engines to improve the performance and service life of the engine.

Manufacturing process

1. Material selection

Select high-quality stainless steel wire, common materials are 304, 316L, etc., to ensure that it has good corrosion resistance and mechanical properties.

2. Woven wire mesh

The stainless steel wire is woven into a wire mesh with a specific mesh size and shape through professional weaving equipment.

3. Folding and pressing

The woven wire mesh is folded in multiple layers according to the design requirements, and pressed under a certain pressure to initially form a disc shape.

4. High-temperature sintering

The pressed disc is placed in a high-temperature furnace for sintering. Under the action of high temperature, the stainless steel wires fuse with each other to form a solid whole.

5. Post-processing

The sintered filter disc also needs some post-processing processes, such as surface finishing, cleaning, testing, etc., to ensure that its quality meets the requirements.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: round stainless steel sintered mesh filter disc, China, factory, price, buy, Industrial Oil Filter, hydraulic high flow rate water filter, Automatic Self Cleaning Filter, oil mist filter in air compressor system, 5 micron industrial oil filter, durable lube oil filter elements