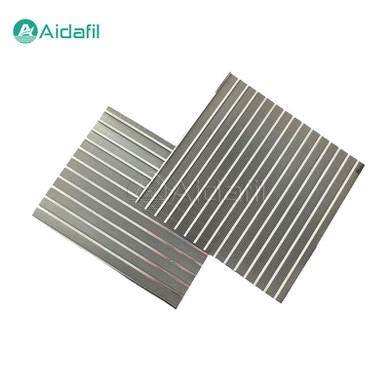

Stainless Steel Wedge Wire Screen Panel

Product Details

The stainless steel wedge wire screen panel is a filter material with unique structure and excellent performance, which plays a vital role in many industrial fields. It has become an important part of the filtration industry with its high precision, high strength, corrosion resistance and good filtration effect.

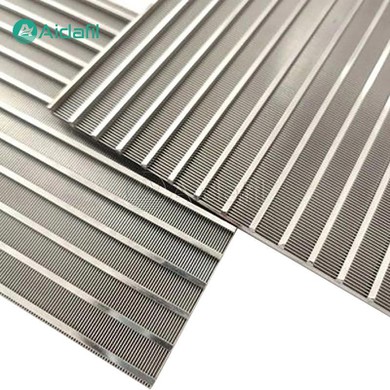

Structure

The stainless steel wedge wire screen panel is welded by stainless steel wedge wire and support bar. The shape of the wedge wire is wedge-shaped, with its narrow end facing the filtration direction and the wide end welded and fixed to the support bar. This special structure makes the screen panel have a larger opening area and smaller filtration resistance, while ensuring the strength and stability of the screen panel.

Characteristics

1. High-precision filtration

Due to the special shape of the wedge wire and the uniform gap distribution, the stainless steel wedge wire screen panel can achieve high-precision filtration and filter out tiny particles and impurities.

2. High strength

The stainless steel material itself has high strength, coupled with a reasonable welding structure, so that the stainless steel wedge wire screen panel has excellent compressive and tensile strength, and can operate stably for a long time in harsh working environments.

3. Corrosion resistance

Stainless steel has good corrosion resistance and can maintain stable performance in corrosive media such as acid, alkali, and salt, extending the service life of the screen panel.

4. Easy to clean

The surface of the stainless steel wedge wire screen panel is smooth and not easy to adhere to impurities. Its structure is easy to clean and can quickly restore the filtering performance through backwashing, ultrasonic cleaning, etc.

5. Good air permeability

The larger opening area ensures that the stainless steel wedge wire screen panel has good air permeability, reduces the pressure loss during the filtration process, and improves the filtration efficiency.

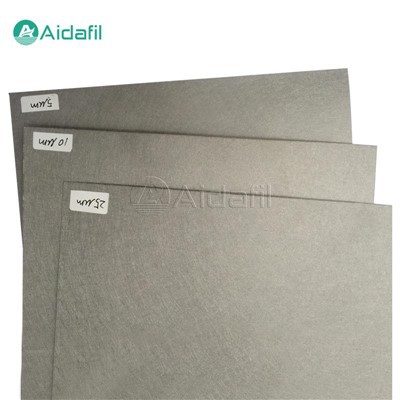

Parameters

|

Material |

Stainless steel 304, 316L, 904L, Hastelloy |

|

Gap |

Minimum 0.015mm |

|

Diameter |

Customized |

|

Filtering direction |

Customized (from inside to outside, or from outside to inside) |

Filtration principle

The filtration principle of the stainless steel wedge wire screen panel mainly includes mechanical interception, surface adsorption and deep filtration.

1. Mechanical interception

When the fluid passes through the screen panel, particles larger than the gap of the screen panel are intercepted by the wedge wire on the surface of the screen panel, thereby achieving solid-liquid separation or gas-solid separation.

2. Surface adsorption

The electrostatic effect and chemical adsorption on the surface of the screen panel can adsorb some tiny particles and impurities, further improving the filtration accuracy.

3. Deep filtration

As the filtration process proceeds, some smaller particles will form filter cakes inside the screen panel, which plays a role of deep filtration and improves the filtration efficiency and service life of the screen panel.

Application

1. Mining

In mineral processing, coal washing and other processes, it is used to separate impurities in ore and coal to improve the grade of ore and coal.

2. Petrochemical

It is used for filtering and separating petroleum and chemical products, such as crude oil filtration, catalyst recovery, chemical solution filtration, etc.

3. Food and Beverage

In food processing and beverage production, it is used to filter impurities and microorganisms in liquids such as juice, milk, beer, etc. to ensure product quality and safety.

4. Environmental Protection

It is used in environmental protection projects such as sewage treatment and waste gas treatment to remove suspended matter in sewage and particulate matter in waste gas to protect the environment.

5. Pharmaceuticals

In the pharmaceutical industry, it is used for filtering and sterilizing drug liquids to ensure the purity and quality of drugs.

6. Electronics

It is used in ultrapure water preparation, chip manufacturing and other processes in the electronics industry to filter tiny particles and impurities to ensure the cleanliness of the production process.

Maintenance

In order to ensure the normal operation and service life of the stainless steel wedge wire screen panel, regular maintenance and care are required:

1. Regular cleaning: According to the use of the screen panel, clean it regularly to remove impurities and dirt on the surface and inside of the screen panel.

2. Check the weld: Regularly check whether the weld of the screen panel is firm. If there is cracking or loosening, repair it in time.

3. Replace the screen panel: When the filtering performance of the screen panel decreases or is seriously damaged, replace it with a new one in time.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: stainless steel wedge wire screen panel, China, factory, price, buy, Hydraulic Filter Element, duplex basket strainer against large particles, Oil Filter Element, coalescing filters for oil removal, 3um compressed air coalescing filter, Oil Separator Filter

Inquiry

You Might Also Like

-

![Large Capacity Stainless Steel Fiber Sintered Felt]()

Large Capacity Stainless Steel Fiber Sintered Felt

-

![Stable Structure Perforated Plate Composite Sintered Mesh]()

Stable Structure Perforated Plate Composite Sintered...

-

![Metal Fiber Sintered Felt With Protective Net]()

Metal Fiber Sintered Felt With Protective Net

-

![High-Strength Stainless Steel Fiber Sintered Felt]()

High-Strength Stainless Steel Fiber Sintered Felt

-

![High Performance Perforated Plate Metal Sintered Mesh]()

High Performance Perforated Plate Metal Sintered Mesh

-

![Durable Standard 5-Layer Sintered Wire Mesh]()

Durable Standard 5-Layer Sintered Wire Mesh