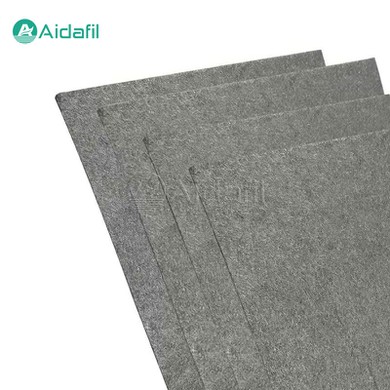

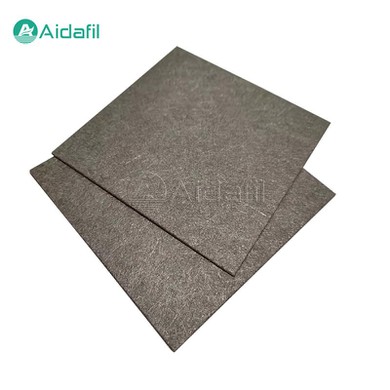

Good High Temperature Resistance Titanium Fiber Sintered Felt

Product Details

The good high temperature resistance titanium fiber sintered felt is a non-woven material composed of titanium fibers. It is composed of countless tiny titanium fibers arranged in an interlaced manner to form a felt-like structure.

Titanium fiber sintered felt has the characteristics of high porosity and simple manufacturing process. It is currently the mainstream material for the porous transport layer of the anode of PEM electrolyzer. Its unique three-dimensional network fiber and fully interconnected pore structure give it a series of special functions. For example, in hydrogen production applications, at 60°C under normal pressure, titanium felt has the best electrolytic performance, the most suitable pore size, the best air permeability and porosity.

On the cathode side of the PEM electrolyzer, the porous transport layer materials are mainly carbon paper and carbon cloth. On the anode side of the PEM electrolyzer, since carbon paper is easily corroded, the porous transport layer materials are mainly titanium mesh, titanium particle sintered plate, titanium fiber sintered felt (titanium felt) and other titanium-based materials.

Material properties

The good high temperature resistance titanium fiber sintered felt has the following properties.

1. High porosity. Titanium fiber sintered felt has a high porosity, which enables it to effectively filter and separate liquids and gases.

2. Uniform pore size. Its pore size distribution is uniform and can be customized according to different application requirements.

3. Strong corrosion resistance. Titanium fiber has good corrosion resistance and can be used for a long time in harsh environments such as acid, alkali, and salt.

4. Good high temperature resistance. Titanium fiber sintered felt can maintain stable performance in high temperature environments and is suitable for applications such as high temperature filtration and separation.

5. High mechanical strength. Although titanium fiber sintered felt is soft in texture, it has high mechanical strength and can withstand certain pressure and stretching.

Parameters

|

High porosity |

60-70% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

|

Low porosity |

50-60% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

Application fields

The good high temperature resistance titanium fiber sintered felt has the following applications.

1. Filtration and separation

Titanium fiber sintered felt is widely used in the filtration and separation of liquids and gases, such as filtration systems in chemical, petroleum, pharmaceutical, food and other industries.

2. Catalyst carrier

Due to its high porosity and good chemical stability, titanium fiber sintered felt can be used as a catalyst carrier to improve the activity and selectivity of the catalyst.

3. Electrode material

In the field of electrochemistry, titanium fiber sintered felt can be used to prepare electrodes, such as gas diffusion layers in fuel cells.

4. Sound absorption and heat insulation

Titanium fiber sintered felt has certain sound absorption and heat insulation properties and can be used in applications in acoustics and thermal fields.

5. Biomedicine

Titanium fiber has good biocompatibility and can be used in the biomedical field, such as the manufacture of artificial organs, medical devices, etc.

Advantages

1. Excellent filtration performance, can effectively remove tiny particles and impurities.

2. Good corrosion resistance and high temperature resistance, suitable for various harsh environments.

3. Strong customizability, the pore size and porosity can be adjusted according to different application requirements.

4. Relatively low cost, it has certain competitiveness compared with other high-performance filter materials.

Manufacturing process

1. Preparation of titanium fiber. Titanium alloy wire or titanium powder is usually used as raw material, and it is made into micron-sized titanium fiber through processes such as wire drawing and fiberization.

2. Non-woven paving. The titanium fiber is evenly laid on the mold or carrier by non-woven laying method to form a felt structure.

3. High temperature sintering. The laid titanium fiber felt is placed in a high temperature furnace for sintering, so that the titanium fibers are connected to each other to form a solid whole.

4. Post-processing. According to specific needs, the sintered titanium fiber felt is further processed, such as surface coating, cutting, folding, etc.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: good high temperature resistance titanium fiber sintered felt, China, factory, price, buy, rigid structure sintered metal filter cartridge, 8mm wire wedge wire filter, Stainless Steel Duplex Strainer, Machine Oil Filter, 500um stainless steel duplex strainer, air filter compressor with filter paper