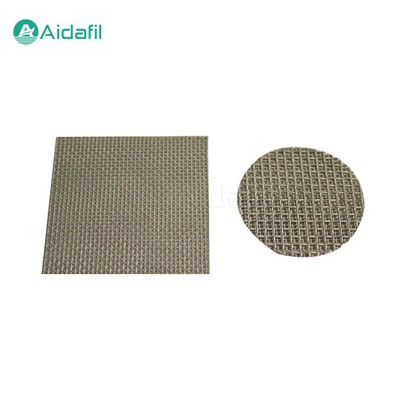

High-Performance Titanium Powder Sintered Filter Disc

Product Details

The high-performance titanium powder sintered filter disc is mainly used in filtration applications that require high temperature resistance, corrosion resistance, and high mechanical strength. It combines the excellent physical and chemical properties of titanium metal with the flexibility of powder metallurgy technology to provide high-efficiency and high-stability filtration solutions for many industries.

Technical features and performance advantages

1. Corrosion resistance

Titanium itself is highly resistant to corrosion and is almost immune to corrosion by seawater, various acid-base solutions, and organic compounds. It is particularly suitable for filtration applications in harsh environments such as chemical and marine engineering.

2. High temperature resistance

Titanium powder sintered filter disc can maintain good mechanical properties and chemical stability at operating temperatures up to 300°C, making them suitable for filtration of high-temperature gases or liquids.

3. Filtration accuracy and permeability

By adjusting the powder particle size, molding pressure, and sintering parameters, the pore size and distribution of the filter disc can be flexibly controlled, thus achieving filtration accuracy from micron to sub-micron level while maintaining good permeability.

4. High strength and long life

The sintered titanium filter disc has a high density and uniform microstructure, which endows it with excellent mechanical strength and fatigue resistance. It can maintain long-term stable operation and prolong service life even under high pressure difference or frequent operating conditions.

5. Biocompatibility

Titanium is one of the commonly used materials in the biomedical field, and its good biocompatibility and non-toxicity make it an ideal choice for filtration in pharmaceuticals and bioengineering.

Parameters

|

|

Value of particles blocked in liquid |

Permeability (no less than) |

|||

|

Model |

Filtration efficiency (98%) |

Filtration efficiency (99.9%) |

Permeability (10-12m2) |

Relative permeability |

MPa |

|

ADTG-1 |

1 |

3 |

0.05 |

5 |

3 |

|

ADTG-3 |

3 |

5 |

0.08 |

8 |

3 |

|

ADTG-5 |

5 |

10 |

0.3 |

30 |

3 |

|

ADTG-10 |

10 |

14 |

0.8 |

80 |

3 |

|

ADTG-15 |

15 |

20 |

1.5 |

150 |

3 |

|

ADTG-20 |

20 |

32 |

2 |

200 |

3 |

|

ADTG-35 |

35 |

52 |

4 |

400 |

2.5 |

|

ADTG-60 |

60 |

85 |

6 |

600 |

2.5 |

|

ADTG-80 |

80 |

124 |

10 |

1000 |

2.5 |

Application field

1. Medicine and biotechnology

In the process of drug purification, cell culture, vaccine production, etc., titanium powder sintered filter disc can effectively filter microorganisms and tiny particles to ensure the purity and safety of the product.

2. Water treatment

In the fields of seawater desalination, drinking water treatment, and industrial wastewater treatment, titanium powder sintered filter disc can resist corrosion of various water quality and effectively remove suspended solids, bacteria, and viruses.

3. Chemical and petrochemical

In the process of chemical reaction, solvent filtration, gas purification, etc., the corrosion resistance and high temperature resistance of titanium powder sintered filter disc are unmatched by other materials.

4. Food & Beverage

It is used for clarification and filtration of fruit juices, beer, dairy products, etc., to ensure food quality and hygiene.

5. Electronic semiconductor

In semiconductor manufacturing processes such as ultrapure water systems and etchant circulation, titanium powder sintered filter disc can effectively remove particles and prevent contamination.

6. Metallurgy

In high-temperature operations such as metal smelting and casting, titanium powder sintered filter disc is used to filter gases or melts to improve product quality.

Manufacturing principle

The production process of high-performance titanium powder sintered filter disc is a highly technology-intensive process, which mainly includes multiple links such as raw material selection, powder preparation, molding, sintering, and post-processing.

1. Raw material selection and powder preparation

Titanium metal with high purity (usually ≥ 99.4%) is selected as the raw material, and titanium metal is converted into fine and uniform powder by gas atomization, water atomization or rotating electrode method. The particle size of the powder directly affects the pore structure and filtration accuracy of the final product, so particle size control is extremely critical.

2. Molding

The pretreated titanium powder is put into a mold, and it is molded into a filter body of the desired shape and size by cold isostatic pressing, molding or injection molding. At this stage, the density and pore distribution of the filter can be precisely controlled by adjusting the mold design and pressure conditions.

3. Sintering

The formed green body is sintered at high temperature in a protective atmosphere (such as argon), and the temperature is usually between 1200 ° C and 1400 ° C. During the sintering process, neck growth occurs between the titanium powder particles to form a solid connection while maintaining a certain pore structure. Precise control of sintering time and temperature is crucial to the mechanical properties and pore characteristics of the product.

4. Post-processing

After sintering, the product may also need to go through machining (e.g. cutting, grinding), heat treatment, surface treatment, and other steps to achieve final dimensional accuracy, surface finish, and enhanced specific properties.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: high-performance titanium powder sintered filter disc, China, factory, price, buy, natural gas dehydration filter elements, Coalescer Filter Cartridge, 100 m automatic self cleaning filter, corrosion resistant oil mist filter, 0 1 m coalescing filter cartridge, Hydraulic Oil Filter Cartridge