Metal Mat-Shaped Sintered Mesh

Product Details

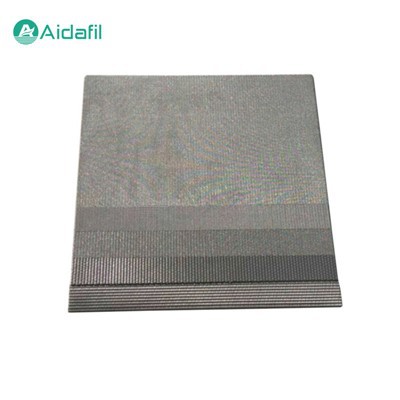

The metal mat-shaped sintered mesh is a high-performance filter material made of multiple layers of metal woven wire mesh stacked and made through a vacuum sintering process. It is named after its unique mat shape, that is, the mesh holes between the layers of wire mesh are interlaced to form a continuous and uniform filter structure. This structure not only improves the filtration efficiency, but also enhances its mechanical strength and deformation resistance, making it an ideal choice for precision filtration.

The metal mat-shaped sintered mesh not only overcomes the shortcomings of low strength, poor rigidity and unstable mesh shape of ordinary wire mesh, but also can reasonably match and design the pore size, permeability and mechanical strength of the material, so that it has excellent filtration accuracy, filtration resistance and anti-deformation ability.

The manufacturing process of the metal mat-shaped sintered mesh is very critical, involving precise lamination pressing and high-temperature sintering. First, high-precision metal woven wire mesh is selected as the basic material, and then wire meshes of different mesh sizes are stacked together in a specific order. Then, through precise lamination pressing equipment, the layers of wire mesh are closely fitted and formed into a uniform mat-like structure. Finally, high-temperature sintering is carried out under vacuum conditions to melt and combine the contact points between the layers of metal wire mesh to form an integral sintered mesh.

Features

The main features of the metal mat-shaped sintered mesh include:

1. High mechanical strength. Due to the special manufacturing process, the metal mat-shaped sintered mesh has high overall rigidity and tensile strength, and can remain stable under high pressure and high flow rate.

2. Precise filtration. Its mat-like structure makes the filtration effect more precise and can effectively remove tiny particles in liquids or gases.

3. Good permeability. The reasonable pore structure makes the metal mat-shaped sintered mesh have high flow capacity and low pressure loss while ensuring filtration accuracy.

4. Corrosion resistance. It is usually made of corrosion-resistant materials such as stainless steel and can be used in various acid and alkali environments.

5. Easy to clean and maintain. The metal mat-shaped sintered mesh can be easily backwashed or other cleaning operations to extend its service life.

Application

The application fields of the metal mat-shaped sintered mesh are quite wide, including but not limited to:

- Chemical industry: Used for filtration of fine chemicals, such as catalyst recovery and purification.

- Petrochemical: Separation and purification of various media in the process of petroleum refining and chemical production.

- Water treatment: Used for impurity filtration in drinking water, industrial water and wastewater treatment.

- Food and beverage: In food processing and beverage manufacturing, to ensure product purity and hygienic safety.

- Pharmaceutical field: In drug production, to refine raw materials and purify drugs before packaging.

Model parameters

|

Model number |

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

ADBSW1 |

1 |

6-7 |

180 |

5300-6000 |

|

ADBSW2 |

2 |

8-9 |

240 |

4300-5000 |

|

ADBSW5 |

5 |

11-13 |

260 |

3000-3700 |

|

ADBSW10 |

10 |

16-18 |

310 |

2700-3300 |

|

ADBSW15 |

15 |

24-26 |

350 |

2000-2600 |

|

ADBSW20 |

20 |

28-32 |

450 |

1800-2300 |

|

ADBSW25 |

25 |

34-36 |

620 |

1400-1900 |

|

ADBSW30 |

30 |

40-45 |

690 |

1200-1700 |

|

ADBSW40 |

40 |

50-55 |

720 |

1000-1500 |

|

ADBSW50 |

50 |

71-80 |

850 |

900-1200 |

|

ADBSW70 |

70 |

89-95 |

900 |

700-1100 |

|

ADBSW100 |

100 |

110-120 |

1080 |

650-1000 |

|

ADBSW150 |

150 |

180-200 |

2600 |

550-800 |

|

ADBSW200 |

200 |

260-280 |

2800 |

450-600 |

Precautions for use

1. Avoid overloading. Do not allow the mat-shaped sintered mesh to withstand loads that exceed its maximum design pressure and flow rate.

2. Monitor the pressure difference. The normal pressure difference should be kept within the recommended range. Excessive pressure difference may cause damage or failure of the sintered mesh.

3. Regular cleaning. Regularly clean the mat-shaped sintered net according to the usage to remove accumulated impurities and dirt.

4. Avoid physical damage. Handle the sintered net with care when handling it to avoid physical damage.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: metal mat-shaped sintered mesh, China, factory, price, buy, cartridge compressed air coalescing filter, plastic machine oil filter, Single Bag Filter Housing, Screw Compressor Oil Filter, Stainless Steel Duplex Strainer, Lubricating Oil Filter Element