Multi-Layer Sintered Monel Wire Mesh

Product Details

The multi-layer sintered monel wire mesh is a multi-layer sintered filter material made of Monel 400 alloy. The material plays a crucial role in many industrial fields due to its excellent corrosion resistance and high temperature resistance.

The multi-layer sintered monel wire mesh plays an important role in power plant feed water system, steam generating pipe filtration, seawater desalination plant and other fields with its excellent corrosion resistance and high temperature resistance. Its multi-layer sintering structure and manufacturing process ensure efficient filtration performance and long service life.

Basic characteristics of Monel 400 alloy

1. Corrosion resistance: Monel 400 alloy contains nickel and copper, both of which have good corrosion resistance.

2. High temperature resistance: The high temperature properties of the alloy enable it to remain stable at extreme temperatures and resist deformation.

3. Mechanical strength: The alloy has high mechanical strength and can withstand greater pressure and impact.

Manufacturing process of multi-layer sintered monel wire mesh

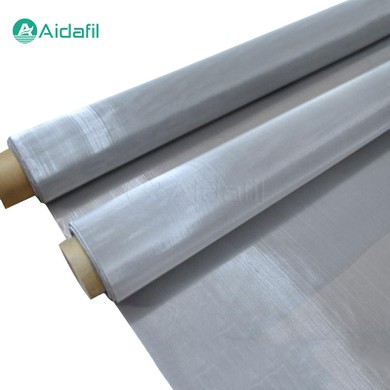

1. Woven wire mesh. Multi-layer Monel alloy woven wire mesh is used as the base material.

2. Superposition combination. The multi-layer woven wire mesh is superimposed and combined to increase the thickness and strength of the filter material.

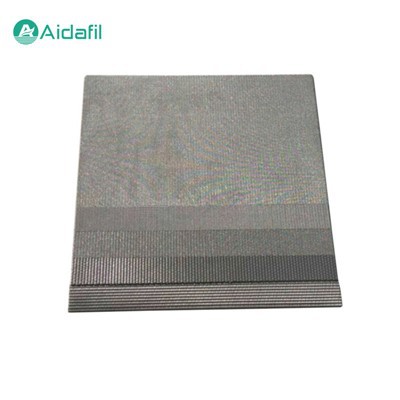

3. Vacuum sintering. Vacuum sintering is performed in a vacuum sintering furnace to ensure the purity and structural stability of the material.

4. Gas pressurization and rolling. By gas pressurization and rolling in a rolling mill, the density and flatness of the sintered mesh are further improved.

Application field of multi-layer sintered monel wire mesh

1. Power plant water supply system. In the power plant's water supply system, the sintered monel wire mesh is used for filtration to ensure the purity of water quality.

2. Steam Generating Pipe Filtration. In the steam generating pipe, the filter material needs to be resistant to high temperature and corrosion, and sintered monel wire mesh is the ideal choice.

3. Seawater Desalination Plant. In the process of seawater desalination, sintered monel wire mesh is used for seawater slag removal to improve desalination efficiency and quality.

Model parameters

|

Model number |

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

ADBSW1 |

1 |

6-7 |

180 |

5300-6000 |

|

ADBSW2 |

2 |

8-9 |

240 |

4300-5000 |

|

ADBSW5 |

5 |

11-13 |

260 |

3000-3700 |

|

ADBSW10 |

10 |

16-18 |

310 |

2700-3300 |

|

ADBSW15 |

15 |

24-26 |

350 |

2000-2600 |

|

ADBSW20 |

20 |

28-32 |

450 |

1800-2300 |

|

ADBSW25 |

25 |

34-36 |

620 |

1400-1900 |

|

ADBSW30 |

30 |

40-45 |

690 |

1200-1700 |

|

ADBSW40 |

40 |

50-55 |

720 |

1000-1500 |

|

ADBSW50 |

50 |

71-80 |

850 |

900-1200 |

|

ADBSW70 |

70 |

89-95 |

900 |

700-1100 |

|

ADBSW100 |

100 |

110-120 |

1080 |

650-1000 |

|

ADBSW150 |

150 |

180-200 |

2600 |

550-800 |

|

ADBSW200 |

200 |

260-280 |

2800 |

450-600 |

Advantages of multi-layer sintered monel wire mesh

1. Resistant to high corrosive environments. The sintered monel wire mesh can be used for a long time in highly corrosive environments and is not easily corroded.

2. Adapt to high temperature conditions. Under high temperature conditions, the sintered monel wire mesh can still maintain good filtration performance.

3. High filtration efficiency. The multi-layer sintered structure makes filtration more efficient and can effectively intercept tiny particles.

4. Long service life. Due to its excellent corrosion resistance and high temperature resistance, the sintered monel wire mesh has a long service life.

Environmental impact of multi-layer sintered monel wire mesh

1. Environmental performance. The use of the sintered monel wire mesh helps to improve the environmental performance of industrial filtration and reduce pollutant emissions.

2. Sustainable development. As a durable filter material, the sintered monel wire mesh is in line with the concept of sustainable development.

Economic Benefits of multi-layer sintered monel wire mesh

1. Reduced maintenance costs. Although the initial investment is high, it can reduce maintenance and replacement costs in the long run due to its durability.

2. Improve production efficiency. Efficient filtration performance can improve the operating efficiency of the entire system, thus enhancing production efficiency.

In addition, when selecting and using multi-layer sintered monel wire mesh, users need to consider factors such as:

1. Working environment. Select the appropriate filter material according to the specific working environment (e.g. temperature, pressure, corrosiveness, etc.).

2. Filtration accuracy. Choose the appropriate mesh size according to the particle size to be filtered.

3. Cost budget. Make a reasonable cost budget considering the initial investment and long-term operating costs.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: multi-layer sintered monel wire mesh, China, factory, price, buy, Return Oil Filter, stable sintered metal filter cartridge, welded structure wedge wire filter, 60micron stainless steel sintered wire mesh, sintered wire mesh for punching, 2 microns sintered filter disc