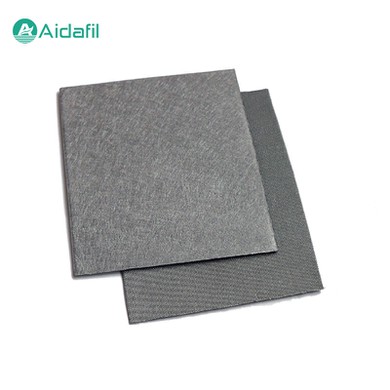

Protection Mesh Sintered Felt

Product Details

The protection mesh sintered felt is a high-performance filter material. It is made of metal fibers through a high-temperature sintering process and has the characteristics of multi-layer structure, high porosity, large specific surface area and uniform pore size distribution.

The protection mesh sintered felt is usually made of high temperature and corrosion-resistant metal materials such as stainless steel. These materials endow the sintered felt with excellent mechanical properties and chemical stability, enabling it to be used for a long time in harsh industrial environments.

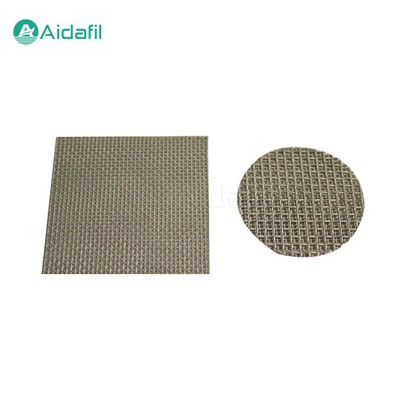

The protection mesh sintered felt as a three-dimensional mesh-like porous structure, which not only provides high porosity and large surface area, but also makes the filtration accuracy higher and the pollution capacity larger. Compared with traditional metal filters, sintered felt is not easy to clog and damage, and can withstand higher pressure and temperature.

Due to its special structure and material, the protection mesh sintered felt performs well in filtration efficiency and precision. It can effectively remove tiny particles from the fluid while maintaining low pressure loss and large flow rate. This makes the sintered felt ideal for many high-precision filtration applications.

Model parameters

|

Model |

Filter precision (μm) |

Bubbling point pressure (pa) |

Air permeability (L/min, dm2, kpa) |

Porosity (%) |

Containment capacity (mg/cm2) |

Thickness (mm) |

Fracture strength (Mpa) |

|

Basic value |

Basic value |

Basic value |

Basic value |

Basic value |

Basic value |

||

|

ADZB-5 |

5 |

6800 |

47 |

75 |

5 |

0.3 |

32 |

|

ADZB-7 |

7 |

5200 |

63 |

76 |

6.5 |

0.3 |

36 |

|

ADZB-10 |

10 |

3700 |

105 |

75 |

7.8 |

0.37 |

32 |

|

ADZB-15 |

15 |

2450 |

205 |

79 |

8.6 |

0.4 |

23 |

|

ADZB-20 |

20 |

1900 |

280 |

80 |

15.5 |

0.48 |

23 |

|

ADZB-25 |

25 |

1550 |

355 |

80 |

19 |

0.62 |

20 |

|

ADZB-30 |

30 |

1200 |

520 |

80 |

26 |

0.63 |

23 |

|

ADZB-40 |

40 |

950 |

670 |

78 |

29 |

0.68 |

26 |

|

ADZB-60 |

60 |

630 |

1300 |

85 |

36 |

0.62 |

28 |

|

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Material

The following are two common types of protection mesh sintered felt materials:

1. Stainless steel material

Stainless steel is one of the most commonly used materials in the manufacture of the protection mesh sintered felt. It includes various types such as 304, 316 and 316L. These stainless steel materials not only have good corrosion resistance, but also can be used for a long time at temperatures up to 600°C. Due to its excellent mechanical properties and chemical stability, stainless steel sintered felt is widely used in liquid and gas filtration in chemical, pharmaceutical, food processing and other fields.

2. Fe-Cr-Al fiber material

Fe-Cr-Al fiber is another important material used in the production of the protection mesh sintered felt. This material is characterized by its ability to maintain stability and corrosion resistance at extremely high temperatures (up to 1200°C). Fe-Cr-Al fiber membranes are widely used in the fields of internal combustion engine exhaust purification, high temperature flue gas dust removal, and heating furnaces due to their high temperature resistance.

Application

The protection mesh sintered felt is widely used in the fields of chemical industry, medicine, hydraulic system filtration and environmental protection.

1. Chemical industry

In the chemical industry, the protection mesh sintered felt is mainly used for the filtration and purification of high-temperature, corrosive liquids. Since their materials are usually high-temperature and corrosion-resistant metal materials such as stainless steel or Fe-Cr-Al fibers, this enables them to effectively remove tiny particles from fluids during chemical processes, while maintaining low pressure losses and large flow rates. These characteristics make protection mesh sintered felt an ideal choice for filtering and purifying various chemicals in the chemical industry.

2. Pharmaceutical industry

In the pharmaceutical industry, the application of the protection mesh sintered felt is mainly reflected in the clarification of various liquids. Due to its high porosity and large specific surface area, sintered mats can effectively remove suspended solids and other contaminants in liquids, ensuring the safety and purity of pharmaceutical production. Especially in biopharmaceuticals, protection mesh sintered felts are favored for their cleaning and regeneration properties for extremely demanding sterile filtration conditions.

3. Hydraulic system filtration

The protection mesh sintered felt also plays an important role in the filtration of hydraulic systems. It can be made into low, medium and high pressure filters and is widely used in aerospace, aviation, marine, machine tool, metallurgy and other industries. In these applications, sintered felt not only needs to withstand high working pressure, but also needs to maintain stable filtration performance for a long time. The design of the protection mesh further enhances its mechanical strength and durability, making it perform well in these high pressure environments.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: protection mesh sintered felt, China, factory, price, buy, high precision transformer oil filter cartridge, sintered filter disc for drying, turbine high pressure oil filter, High Flow Rate Water Filter, 2 microns sintered filter disc, Automatic Self Cleaning Filter