Strong Effective Perforated Plate Composite Sintered Mesh

Product Details

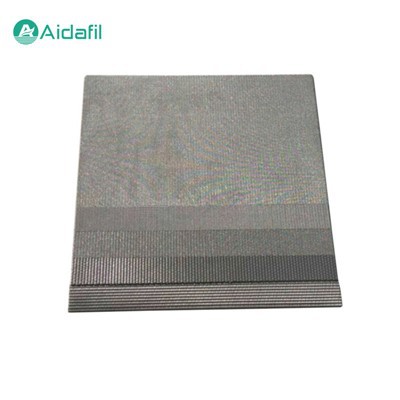

The strong effective perforated plate composite sintered mesh is a filter material formed by sintering a perforated plate and a flat-woven mesh at the base layer. It has high compressive strength and mechanical strength, as well as the characteristics of high flow and easy cleaning. This material can be vacuum sintered through a special combination of perforated plate and wire mesh according to different pressure and filtration accuracy requirements.

Structure and features

The basic structure of the strong effective perforated plate composite sintered mesh is composed of multiple layers of metal wire mesh and one or more layers of perforated plates alternately superimposed. During the sintering process, they are firmly combined by vacuum technology to form a filter medium with a complex three-dimensional network structure. This structure not only provides extremely high mechanical strength, but also ensures good filtration effect and fluid passage.

1. High strength

Due to the strong bond between the perforated plate and the wire mesh during the sintering process, the perforated plate composite sintered mesh has high compressive and tensile strength, capable of maintaining stable operation under high pressure and high load working conditions.

2. High filtering efficiency

The metal mesh layer can effectively capture particles of different sizes to achieve accurate filtration effect. At the same time, the design of the perforated plate allows large particles to pass directly, reducing the burden of the mesh layer and prolonging the service life of the filter material.

3. Easy to clean and maintain

The structure of the perforated plate composite sintered mesh allows backwashing, which can effectively remove impurities adhering to the surface and holes, and improve the service life and filtration efficiency of the filter material.

4. Corrosion resistance

Usually made of corrosion-resistant stainless steel, the perforated plate composite sintered mesh can resist a variety of acid and alkali environments and is suitable for the treatment of corrosive materials in the chemical, pharmaceutical and other industries.

Parameters

|

Nominal precision (μm) |

Absolute precision (μm) |

Gases permeability (L/min · dm2 · kPa) |

Bubbling pressure (pa) |

|

1 |

6-7 |

180 |

5300-6000 |

|

2 |

8-9 |

240 |

4300-5000 |

|

5 |

11-13 |

260 |

3000-3700 |

|

10 |

16-18 |

310 |

2700-3300 |

|

15 |

24-26 |

350 |

2000-2600 |

|

20 |

28-32 |

450 |

1800-2300 |

|

25 |

34-36 |

620 |

1400-1900 |

|

30 |

40-45 |

690 |

1200-1700 |

|

40 |

50-55 |

720 |

1000-1500 |

|

50 |

71-80 |

850 |

900-1200 |

|

70 |

89-95 |

900 |

700-1100 |

|

100 |

110-120 |

1080 |

650-1000 |

|

150 |

180-200 |

2600 |

550-800 |

|

200 |

260-280 |

2800 |

450-600 |

Application field

1. Water treatment

In urban water supply, sewage treatment and other fields, the perforated plate composite sintered mesh can be used to remove suspended solids, sediments and other impurities in water to ensure water quality safety.

2. Chemical industry

In the chemical production process, the raw materials and products need to be finely filtered to ensure product quality. The perforated plate composite sintered mesh can effectively filter the tiny particles in the chemical solution.

3. Petrochemical

In petroleum refining and chemical production, the perforated plate composite sintered mesh is used for oil-water separation, catalyst recovery, etc., which helps to improve product purity and reduce resource waste.

4. Metallurgical mining

In metal refining and ore processing, solid-liquid separation is a key step. The perforated plate composite sintered mesh can withstand high temperature and high concentration of corrosive materials.

5. Food industry

In the processing of food and beverages, such as beer, fruit juice, dairy products, etc., the perforated plates and composite sintered mesh is used to ensure product clarification and hygiene.

Manufacturing and selection

--- Manufacturing process

The manufacturing process of the strong effective perforated plate composite sintered mesh includes the following main steps:

1. Punching. Punching the sheet according to the design requirements to form the required pore size and distribution.

2. Layers. Stack perforated plates and wire mesh of different mesh numbers in a specific order.

3. Sintering. The stacked layers are placed in a vacuum sintering furnace and sintered at high temperature.

4. Forming. After sintering, the work in progress goes through cooling, shaping, cutting and other processes, and finally forms the desired shape and size of the perforated plate composite sintered mesh.

--- Selection principle

The following factors should be considered when selecting the appropriate perforated plate composite sintered mesh:

1. Filtration accuracy. Choose the appropriate combination of screen and perforated plate according to the particle size distribution of the material to be filtered.

2. Working pressure. Determine the thickness and structural strength of the product according to the working pressure of the system.

3. Corrosion resistance. Choose the appropriate material according to the chemical properties of the material.

4. Ease of cleaning. Consider whether the production process requires frequent cleaning and the ease of cleaning.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: strong effective perforated plate composite sintered mesh, China, factory, price, buy, pleated cellulose air filter compressor, oil mist filter in air compressor system, industrial oil filter in compressed air system, Coalescer Filter Element, multicolor screw compressor air filter, superior glass fiber air compressor oil separator