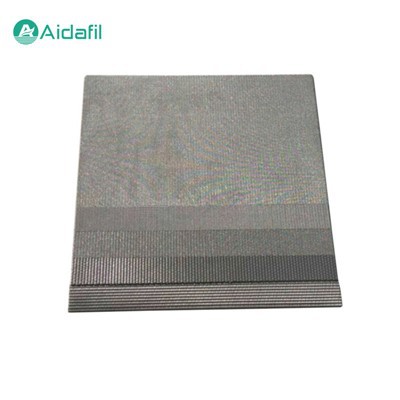

High Quality Stainless Steel Wedge Wire Mesh

Product Details

The high quality stainless steel wedge wire mesh is a screen product made of stainless steel wire through a specific weaving process, with mesh holes in a wedge shape or twill distribution. Compared with traditional plain or square mesh, its unique wedge structure gives higher filtration efficiency and more precise particle control capabilities. This design can not only effectively intercept target particles, but also ensure good permeability, reduce blockage and increase processing capacity.

Material Characteristics

Stainless steel, as the basic material, is the key factor in determining the performance of wedge wire mesh. Common types of stainless steel on the market include but are not limited to 304, 316, 316L, etc. The selection of these materials is mainly based on their excellent corrosion resistance, high temperature resistance, high strength and good processing performance.

- 304 stainless steel

It is one of the most commonly used types of stainless steel, containing 18% chromium and 8% nickel, and is suitable for most less corrosive environments.

- 316 stainless steel

Molybdenum is added to enhance the corrosion resistance to chloride ions, and is suitable for use in seawater or chlorine-containing environments.

- 316L stainless steel

A low-carbon version of 316 stainless steel, which improves welding performance and intergranular corrosion resistance, is particularly suitable for demanding application scenarios.

Production process

The production of the high quality stainless steel wedge wire mesh is a complex process that integrates material selection, weaving, forming, cutting and post-processing.

1. Material preparation

Select the appropriate stainless steel wire according to the application environment and performance requirements of the final product.

2. Weaving

A special weaving machine is used to form the mesh surface through plain, twill or special weaving methods. The uniqueness of the wedge wire mesh lies in its non-uniform mesh design, which requires precise weaving control.

3. Forming and cutting

The woven mesh needs to be cut into specific sizes according to customer needs and formed into the required shape by stamping, welding and other methods.

4. Edge treatment

To prevent edge wear and improve safety, the edges will be treated by hemming, welding or folding.

5. Surface treatment

Finally, the mesh surface may also need electrolytic polishing, passivation treatment, etc. to enhance its corrosion resistance and aesthetics.

Main features

1. Strong corrosion resistance

The stainless steel material enables it to maintain stable performance for a long time in various chemical and natural environments.

2. High filtration accuracy

The wedge-shaped opening can be customized according to actual needs to achieve precise screening from coarse to fine.

3. High strength and durability

The mechanical properties of stainless steel ensure the stability of the mesh surface under high pressure and high flow conditions.

4. Easy to clean and maintain

The smooth surface and reasonable structural design facilitate fast and effective cleaning and maintenance.

5. Strong adaptability

It is widely used in a variety of working conditions and media, and can effectively handle everything from solid particles to liquid suspensions.

Application areas

The application of the high quality stainless steel wedge wire mesh covers almost all industrial fields that require fine filtration and efficient screening:

1. Chemical industry

Filtration of chemical raw materials, separation of reaction products, recovery of catalysts, etc.

2. Mining

Grading of ores, dehydration of mud, recovery of precious minerals.

3. Food processing

Screening of flour, sugar, tea, coffee beans, and clarification and filtration of juice and beverages.

4. Pharmaceutical

Extraction of active ingredients, filtration of liquid medicine, removal of impurities from finished products, meeting GMP standards.

5. Environmental protection

Solid-liquid separation in sewage treatment, air purification, and solid waste treatment.

6. Petroleum and natural gas

Purification of drilling fluid, oil and gas separation, pipeline protection, etc.

Parameters

|

Material |

Stainless steel 304, 316L, 904L, Hastelloy |

|

Gap |

Minimum 0.015mm |

|

Diameter |

Customized |

|

Filtering direction |

Customized (from inside to outside, or from outside to inside) |

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: high quality stainless steel wedge wire mesh, China, factory, price, buy, Compressor Filter Element, oil separator filter for air compressor, good strength stainless steel sintered wire mesh, 2003 honda oil filter element, durable lube oil filter elements, air oil separator for contaminated condensate