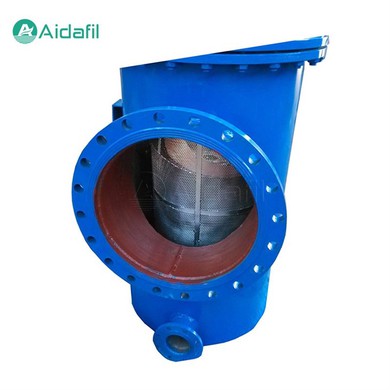

Simple And Efficient Basket Filter

Product Details

The Simple And Efficient Basket Filter's main function is to remove solid particle impurities in liquid to ensure the cleanliness of the liquid system and the normal operation of various equipment. It is widely used in various industrial fields, such as petroleum, chemical, pharmaceutical, food processing, etc.

Working principle

The core part of a basket filter is a filter basket fitted with a filter screen of a specific size. When the liquid passes through the filter, the liquid first enters through the inlet and then passes through the filter basket. During this process, the filter screen in the filter basket can capture solid particles in the liquid, thereby purifying the fluid. The purified fluid flows out from the liquid outlet, while the trapped impurities remain in the filter basket. As the use time increases, the impurities in the filter basket will gradually accumulate, causing the flow channel to clog, and the filter basket needs to be cleaned or replaced.

Features and Advantages

- Easy to install and maintain

The basket filter is usually designed to be very intuitive and easy for users to install and maintain. It is usually equipped with removable filter basket that can be removed for cleaning or replacement with simple operation.

- Efficient filtering

Due to the fact that the basket filter uses a specific size filter screen, it can effectively capture solid particles of different sizes, thus achieving efficient filtration results.

- High customizability

According to different application requirements, the filter screen of the basket filter can be customized to different pore sizes to meet the filtration requirements of different precision.

- Save costs

By using the basket filter, companies can reduce equipment damage and repair costs due to liquid system contamination, while extending the service life of their equipment.

- Environmental protection

Effective filtration of pollutants not only benefits the protection of equipment, but also reduces environmental pollution.

Parameters

|

Material of housing |

Cast iron, carbon steel |

Stainless steel |

|

Material of strainers |

Stainless steel |

|

|

Material of seal components |

Oil-resistant asbestos, flexible graphite, PTFE |

|

|

Working temperature |

-30 ~ +380°C |

-80 ~ +450°C |

|

Filtration precision |

10 ~ 300 meshes |

|

|

Nominal pressure |

0.6 ~ 6.4 Mpa (150Lb ~ 300Lb) |

|

|

Connection |

Flange, welding |

|

Application Scenario

- Industrial production

In various industrial production processes, the basket filter are used to ensure the purity of liquid and to prevent solid particles from causing wear or clogging of equipment.

- Water treatment

In water treatment systems, the basket filter are used to remove suspended solids and impurities from the water, providing a cleaner water source.

- Food and beverage industry

In the manufacturing of food and beverages, the basket filter help ensure the quality and safety of the product, preventing solid particles from entering the final product.

- Pharmaceutical industry

In the pharmaceutical industry, cleanliness requirements are extremely high, and the basket filter are used to ensure liquid cleanliness during the production and packaging of pharmaceuticals.

How to Choose the Right Basket Filter

When selecting the right basket filter, several factors need to be taken into account:

- Fluid properties. Including temperature, pressure, chemical compatibility, etc.

- Filtration accuracy. Select the appropriate filter aperture according to the size of the particles to be removed.

- Flow requirements. Select the corresponding size filter according to the requirements of the system to ensure sufficient flow capacity.

- Application Environment. Taking into account installation space, operating conditions, and any special environmental requirements.

Maintenance and Cleaning

In order to ensure the long-term and effective operation of the basket filter, regular cleaning and maintenance are necessary.

- Regularly check the filter basket for contamination and clean or replace it as needed.

- When cleaning, you can use suitable cleaning agents and tools to remove impurities from the filter screen.

- During maintenance, it is necessary to observe the working pressure of the filter to determine whether it needs to be cleaned in advance.

FAQ

1. Q: What is the function of a filter?

A: The main function of a filter is to remove solid particles, impurities, and harmful substances from liquids or gases, in order to achieve purification, clarification, and protection of equipment.

2. Q: How to choose a suitable filter?

A: When choosing a filter, factors such as the properties of the material being filtered (e.g., viscosity, temperature, corrosion), required filtration accuracy, processing capacity, operating pressure and medium, as well as the type, material, size, and installation method of the filter should be considered.

3. Q: What is the working principle of a filter?

A: The working principle of a filter mainly relies on physical screening, deep interception, absorption, or chemical reactions to remove impurities or harmful components from the material being filtered.

4. Q: How to maintain and care for a filter?

A: Maintenance of filters includes regular cleaning or replacement of filter elements, inspection of seals and fasteners, maintaining stable operating pressure, and avoiding overloading. Specific methods should be referenced from the filter's instruction manual and maintenance guides.

5. Q: What is the service life of a filter?

A: The service life of a filter depends on its working environment, processing volume, and filtration accuracy. Generally, when the filter's pressure drop reaches a certain value or the filtration effect decreases significantly, it needs to be replaced or cleaned.

6. Q: What should be paid attention to during filter installation?

A: During filter installation, attention should be paid to the directionality, ensuring that the fluid enters and exits from the correct ports. Also, the piping system should be cleaned before installation, and the filter should be securely fastened and sealed as required by the instructions.

7. Q: What is the replacement cycle for filters?

A: The replacement cycle for filters depends on their working conditions and filtration requirements, and is usually indicated by pressure difference indicators or timers. When the filter's pressure drop reaches the set value or the filtration effect decreases, it should be replaced in a timely manner.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: simple and efficient basket filter, China, factory, price, buy, hydraulic oil filter cartridge in lubricating, hydraulic oil filter cartridge for power plant, compressor air oil separator in screw compressor, airtight sealing air filter element, natural gas dehydration filter elements, Gas Coalescing Filter