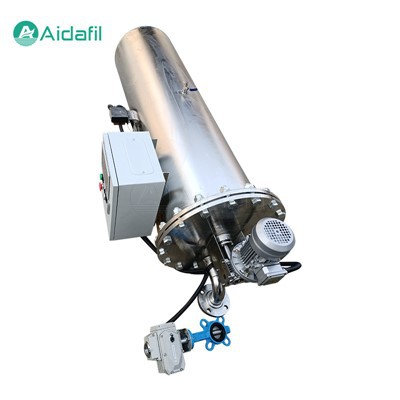

Solid-Structure Duplex Filter For Water System

Product Details

The solid-structure duplex filter for water system is mainly composed of two filter housings, filter elements, sealing rings, flanges and other components. The two filter housings are installed side by side to form a whole. Each filter housing is equipped with a certain number of filter elements. The filter elements are usually made of stainless steel mesh or other corrosion-resistant materials.

When the water flows through the duplex filter, it first enters the first filter housing. Here, the impurities in the water are trapped by the filter cartridge, while the clean water flows into the second filter housing through the filter cartridge. In the second filter housing, it is filtered again by the filter cartridge to ensure the quality of the effluent water.

Due to the parallel design of two filter housings, even if one of the filters malfunctions, the other filter can still function normally, ensuring the continuous operation of the system.

Parameters

|

Material |

Stainless steel or carbon steel |

|

Filtration areas |

5.0 m2, 10 m2, 15 m2, 20 m2, 25 m2, 30 m2, 40 m2 |

|

Filtration accuracy |

0.3, 0.5, 1.5, 10, 15, 25, 50, 100, 200, 300, 400 μm |

|

Design pressure |

0.6 Mpa |

|

Flow rate |

1 ~ 200 m3/h |

|

Working temperature |

5 ~ 80°C |

|

Connections |

Flange |

|

Control way |

Differential Pressure / PLC Timer / Manual |

|

Rated operating voltage |

3PH 380V 50Hz |

Advantages

1. Good filtration effect. The duplex filter adopts two-stage filtration, and the filtration effect is more stable and reliable.

2. Simple structure. The duplex filter has a compact structure, a small footprint, and easy installation.

3. Stable operation. The duplex filter is automatically controlled, eliminating the need for manual intervention during operation, reducing labor costs.

4. Easy maintenance. The filter element of the duplex filter is easy to replace and clean, reducing maintenance costs.

5. Strong adaptability. The duplex filter can be applied to the water treatment needs of different industries and fields, and has strong adaptability.

Application fields

The solid-structure duplex filter for water system finds wide applications in many industries.

1. Industrial field

The duplex filter is widely used in chemical, pharmaceutical, food and beverage, metallurgy, petroleum and other industries to purify production water, process water, etc.

2. Agriculture

The duplex filter is used in irrigation, aquaculture, and other fields to improve water quality, promote crop growth, and improve breeding efficiency.

3. Drinking water field

The duplex filter is used in centralized water supply, distributed water supply and other fields to remove impurities such as suspended solids, particulate matter and microorganisms from water and ensure the safety of drinking water for residents.

4. Environmental protection field

The duplex filter is are used in environmental protection projects such as wastewater treatment and wastewater recycling to reduce the content of pollutants in water and realize the reuse of wastewater.

How to use

1. Installation

First close the water inlet valve, and then install the duplex filter on the pipeline that needs to purify the water to ensure that all interfaces are tightly connected and do not leak.

2. Start

Open the water inlet valve to allow water to enter the filter. At this time, pay attention to observe whether there is any leakage, and check whether the pressure gauge of the filter is normal.

3. Filtration

After the water passes through the filter element, the filtration is completed, and the water flowing out of the water outlet should meet the requirements for use.

4. Cleaning

When the pressure difference between the inlet and outlet of the filter is too large, the filter element needs to be cleaned. When cleaning, close the water inlet valve, open the sewage valve, and then backwash the filter element to remove impurities attached to the filter element.

5. Replace the filter element

If the filter element has been used for too long and cannot be cleaned to restore its filtration performance, a new filter element needs to be replaced.

Selection points

1. Water quality analysis. Understand the basic conditions of the water source and choose the appropriate filter material and pore size according to the type and concentration of impurities in the water.

2. Flow demand. Determine the size and filter element configuration of the required filter according to the actual water consumption to ensure that the daily or peak water demand is met.

3. Filtration accuracy. Depending on the application, filtration accuracy is determined. Domestic water may place more emphasis on removing odors and residual chlorine, while industrial water may have higher requirements for particulate removal.

4. Material durability. Consider the use environment and choose corrosion-resistant, long-life shell materials and filter elements.

5. Maintenance convenience. Choose a model that is easy to disassemble, clean, and replace the filter element to reduce maintenance costs.

FAQ

1. Q: What is the function of a filter?

A: The main function of a filter is to remove solid particles, impurities, and harmful substances from liquids or gases, in order to achieve purification, clarification, and protection of equipment.

2. Q: How to choose a suitable filter?

A: When choosing a filter, factors such as the properties of the material being filtered (e.g., viscosity, temperature, corrosion), required filtration accuracy, processing capacity, operating pressure and medium, as well as the type, material, size, and installation method of the filter should be considered.

3. Q: What is the working principle of a filter?

A: The working principle of a filter mainly relies on physical screening, deep interception, absorption, or chemical reactions to remove impurities or harmful components from the material being filtered.

4. Q: How to maintain and care for a filter?

A: Maintenance of filters includes regular cleaning or replacement of filter elements, inspection of seals and fasteners, maintaining stable operating pressure, and avoiding overloading. Specific methods should be referenced from the filter's instruction manual and maintenance guides.

5. Q: What is the service life of a filter?

A: The service life of a filter depends on its working environment, processing volume, and filtration accuracy. Generally, when the filter's pressure drop reaches a certain value or the filtration effect decreases significantly, it needs to be replaced or cleaned.

6. Q: What should be paid attention to during filter installation?

A: During filter installation, attention should be paid to the directionality, ensuring that the fluid enters and exits from the correct ports. Also, the piping system should be cleaned before installation, and the filter should be securely fastened and sealed as required by the instructions.

7. Q: What is the replacement cycle for filters?

A: The replacement cycle for filters depends on their working conditions and filtration requirements, and is usually indicated by pressure difference indicators or timers. When the filter's pressure drop reaches the set value or the filtration effect decreases, it should be replaced in a timely manner.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: solid-structure duplex filter for water system, China, factory, price, buy, high quality ford oil filter element, Carbon Steel Bag Filter Housing, oil coalescing filter for steel plant, high precision transformer oil filter cartridge, spin on separator filter, 500um stainless steel duplex strainer