Durable Stainless Steel Wedge Wire Screen Tube

Product Details

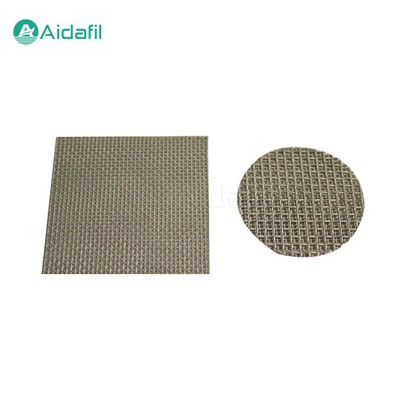

The durable stainless steel wedge wire screen tube, also known as Johnson screen, is a filter material with unique structure and excellent performance. It is mainly composed of profile wire and support ribs, and the profile wire is wound on the support ribs with certain rules to form a tubular structure with specific gaps.

Structural characteristics

1. Wire-wound structure

The profile wire features a wire-wound structure and is made of high-quality stainless steel wire with good corrosion resistance and mechanical strength. The diameter and spacing of the wire can be designed and adjusted according to different filtering needs to achieve different filtering accuracy.

2. Wedge-shaped gap

The gap formed between the wires is wedge-shaped with a wide top and a narrow bottom. This design is conducive to improving filtration efficiency and preventing clogging. Smaller particles can be effectively intercepted, while larger particles are not easy to clog the gap.

3. Support rib

The support rib plays the role of supporting the wire and maintaining the shape of the screen tube. It is also made of materials such as stainless steel and has sufficient strength and rigidity.

Parameters

|

Material |

Stainless steel 304, 316L, 904L, Hastelloy |

|

Gap |

Minimum 0.015mm |

|

Diameter |

Customized |

|

Filtering direction |

Customized (from inside to outside, or from outside to inside) |

Advantages

1. High filtering accuracy

By accurately designing the diameter and spacing of the wire, very high filtering accuracy can be achieved, which can effectively remove tiny particles and impurities.

2. High strength

Made of high-quality materials, it has strong mechanical strength, can withstand greater pressure and water flow impact, and ensure long-term stable operation in harsh working environments.

3. Good corrosion resistance

The corrosion resistance of materials such as stainless steel enables the wedge wire screen tube to be used in various corrosive media and is suitable for a wide range of industrial fields.

4. Good backwashing performance

It is easy to perform backwashing operation. The filter cake can be quickly removed by reverse water flow, the filtering performance can be restored, and the service life of the filter tube can be extended.

5. Large flow

Due to its unique structure and large porosity, the wedge wire screen tube can allow a large fluid flow to pass while ensuring the filtering effect, thereby improving production efficiency.

6. Long service life

With good wear resistance and corrosion resistance, as long as it is used and maintained correctly, its service life is usually long, which can bring long-term economic benefits to users.

Application fields

1. Petrochemical industry

Used for solid-liquid separation in crude oil mining, refining, chemical production and other processes, such as oil well sand control, catalyst recovery, liquid purification, etc.

2. Water treatment field

Play an important role in sewage treatment, seawater desalination, drinking water purification, etc., and removes impurities such as suspended matter and particulate matter in water.

3. Mining and metallurgical industry

Used for ore screening, filtration in ore dressing plants, recovery of metal powders, etc.

4. Food and beverage industry

Ensure the purity of food and beverages, remove impurities and microorganisms.

5. Pharmaceutical industry

Filter the liquid medicine to ensure the quality and safety of the medicine.

6. Environmental protection field

Used for waste gas treatment, dust collection, etc., to reduce environmental pollution.

7. Machinery manufacturing industry

Used for filtering hydraulic systems, lubrication systems, etc., to protect the normal operation of equipment.

Production process

1. Material selection

According to the specific use requirements and environmental conditions, select suitable stainless steel wire or other alloy wire as the wire-wound material, as well as the corresponding support rib material.

2. Wire-wound production

Through special wire-wound equipment, the metal wire is wound on the support rib according to the designed parameters to form a tubular structure with a specific gap.

3. Welding and fixing

The connection points of the profile wire and the support rib are welded and fixed to ensure the stability and strength of the screen tube.

4. Surface treatment

The screen tube is surface treated, such as polishing, passivation, etc., to improve its corrosion resistance and appearance quality.

5. Quality inspection

Strict quality inspection is carried out on the produced wedge wire screen tubes, including tests on filtration accuracy, strength, corrosion resistance, etc., to ensure that the products meet relevant standards and requirements.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: durable stainless steel wedge wire screen tube, China, factory, price, buy, spin on separator filter, Inline Filter Element, Coalescer Filter Element, airtight sealing air filter element, Compressed Air Filter Element, High Pressure Oil Filter