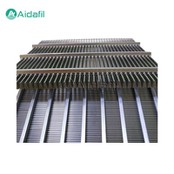

High Porosity Sintered Titanium Powder Plate For Filtration

Product Details

The high porosity sintered titanium powder plate for filtration is a filter material made by powder metallurgy process using titanium powder as raw material. This technology involves sintering titanium powder at high temperature to connect its particles to each other, thus forming a porous and solid structure. This sintering process gives the filter plate excellent mechanical properties and corrosion resistance, making it an ideal choice for filtering applications in special environments.

Manufacturing process

The process of manufacturing the high porosity sintered titanium powder plate for filtration includes the following steps:

1. Powder preparation. First, high-purity titanium metal powder needs to be prepared. This is usually achieved by physical gas grinding of titanium ingots (such as rotating electrode method) or chemical methods (such as hydrogenation dehydrogenation method).

2. Powder screening. In order to ensure that the porous structure after sintering is uniform, the titanium powder needs to be strictly screened by particle size.

3. Pressing and molding. The screened titanium powder is evenly filled into the mold and pressed into shape. This step determines the initial shape and size of the filter plate.

4. Sintering process. The formed titanium powder block is sintered at high temperature under protective atmosphere or vacuum conditions. During the sintering process, solid phase diffusion occurs between titanium powder particles and combines to form a stable porous structure.

5. Post-processing. The sintered filter plate may need to be machined to achieve precise size requirements, or surface treated to improve its anti-fouling ability.

Characteristics

The high porosity sintered titanium powder plate for filtration has the following characteristics:

1. Excellent corrosion resistance

Titanium has natural corrosion resistance, especially for media such as seawater and chloride. This makes sintered titanium powder plates particularly suitable for filtration applications in marine environments and chemical industries.

2. Good thermal stability

The sintered titanium powder plates can work at higher temperatures without performance degradation, and their high temperature resistance is better than that of most polymer filter plates.

3. High strength and rigidity

Due to the high strength of titanium metal itself, the sintered filter plate also maintains this characteristic and can withstand higher working pressures.

4. Fine pore control

The sintering process can accurately control the pore size and distribution, and produce micron or even nanometer filtration accuracy.

5. Cleanliness and regenerative properties

The sintered titanium powder plates can be regenerated by cleaning and backflushing to extend their service life.

Parameters

|

Value of particles blocked in liquid |

Permeability (no less than) |

|||

|

Filtration efficiency (98%) |

Filtration efficiency (99.9%) |

Permeability (10-12m2) |

Relative permeability |

MPa |

|

1 |

3 |

0.05 |

5 |

3 |

|

3 |

5 |

0.08 |

8 |

3 |

|

5 |

10 |

0.3 |

30 |

3 |

|

10 |

14 |

0.8 |

80 |

3 |

|

15 |

20 |

1.5 |

150 |

3 |

|

20 |

32 |

2 |

200 |

3 |

|

35 |

52 |

4 |

400 |

2.5 |

|

60 |

85 |

6 |

600 |

2.5 |

|

80 |

124 |

10 |

1000 |

2.5 |

Application

Due to its excellent performance characteristics, the high porosity sintered titanium powder plate for filtration has found wide applications in many industrial fields:

1. Chemical and petrochemical industries

In the filtration of corrosive liquids and gases, it can provide long-term and stable filtration performance.

2. Food and beverage industry

Used for filtering alcohol, beverages and food oils, etc., in compliance with hygiene standards.

3. Water treatment

Including urban sewage treatment, seawater desalination and water treatment processes in power plants.

4. Pharmaceutical industry

Used for sterile filtration and separation and purification of biological products.

5. Electronic industry

In the production of semiconductors and liquid crystal displays, it is used to filter high-purity chemicals.

6. Metallurgy and mining

Used for filtration in metal recovery and mineral processing.

7. Aerospace

Used in the fuel and life support systems of spacecraft because of its light weight and high temperature resistance.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: high porosity sintered titanium powder plate for filtration, China, factory, price, buy, durable gas coalescing filter, composite materials coalescer filter cartridge, 60um high flow rate water filter, worry free automatic self cleaning filter, polypropylene bag filter housing for water treatment plants, 10um compressor oil filter