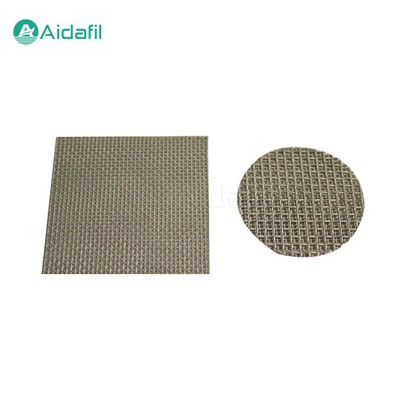

Quality-Assured Metal Wedge Wire Screen Tube

Product Details

The quality-assured metal wedge wire screen tube is a common filter material, usually made of stainless steel or other corrosion-resistant metal materials. It is wound in the form of wedge wire and has good filtering effect and high strength. It is widely used in fluid filtration process in various industrial fields, such as water treatment, oil well sand control, chemical industry, food processing, etc. This screen tube is named after its unique wedge wire structure.

The working principle of the metal wedge wire screen tube mainly relies on screening and deep filtration. When the fluid passes through the screen tube, larger particles will be directly screened out by the surface of the screen tube, and smaller particles may penetrate into the wedge wire and be filtered out by deep filtration. Due to the special structure of the wedge wire, impurities can be effectively intercepted even at a higher flow rate.

Structure and characteristics

The basic structure of the quality-assured metal wedge wire screen tube is that a wedge wire is wound according to a certain rule to form a continuous filtration surface. The cross-section of the wedge wire is usually an isosceles triangle or trapezoid. This shape can make the screen tube have better stability when under pressure. The two ends of the screen tube can be open or closed, depending on the specific application.

The main features of the wedge wire screen tube include:

1. High filtration accuracy. The special structure of the wedge wire enables the screen tube to filter out fine impurities and achieve a high filtration accuracy.

2. High strength. The wedge wire can stably support the screen tube when under pressure, making it not easy to deform.

3. Corrosion resistance. Usually made of stainless steel or other corrosion-resistant materials, it can be used for a long time in harsh environments.

4. Easy to clean. The smooth surface of the wedge wire makes the screen tube easy to clean and can maintain the filtering effect for a long time.

5. Diverse designs. Wedge wire screen tubes of different specifications and shapes can be designed according to different application scenarios and filtering requirements.

Parameters

|

Material |

Stainless steel 304, 316L, 904L, Hastelloy |

|

Gap |

Minimum 0.015mm |

|

Diameter |

Customized |

|

Filtering direction |

Customized (from inside to outside, or from outside to inside) |

Application field

The application field of quality-assured metal wedge wire screen tube is very wide, mainly including the following aspects:

1. Water treatment. In municipal water supply and sewage treatment, it is used to remove suspended matter and particulate matter.

2. Oil well sand control. In oil field exploitation, it prevents sand particles in the formation from entering the wellbore and protects the pumping equipment.

3. Chemical industry. In the production process of chemical products, it is used to filter raw materials and products.

4. Food processing. In the food processing industry, it is used to ensure the cleanliness and safety of food.

5. Pharmaceutical industry. In the pharmaceutical process, it is used for precise filtration of drug solutions.

6. Environmental protection engineering. In waste gas treatment and dust collection, it is used to capture harmful substances.

Customized service

We have the ability to design and produce wedge wire screen tubes according to customer needs. Custom services may include the following:

1. Size customization

According to the size requirements provided by the customer, screen tubes with length, diameter, interface size, etc. that meet specific standards are produced.

2. Material customization

According to the needs of different application environments, stainless steel, carbon steel, alloy steel or other special materials are selected to manufacture screen tubes.

3. Filtration accuracy customization

Adjust the specifications and spacing of the wedge wire to achieve the required filtration accuracy and effect.

4. Structural customization

Customize open or closed screen tubes according to actual working conditions, and select suitable end caps and connection methods.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: quality-assured metal wedge wire screen tube, China, factory, price, buy, Stainless Steel Woven Wire Mesh, industrial oil filter in lubricating, compact stainless steel duplex strainer, lube oil filter elements for steel plant, hydraulic oil filter cartridge in lubricating, fully automatic backwash filter