Stainless Steel Metal Fiber Sintered Felt

Product Details

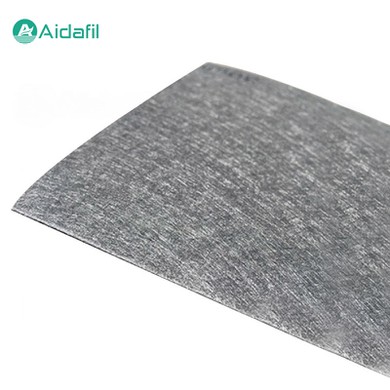

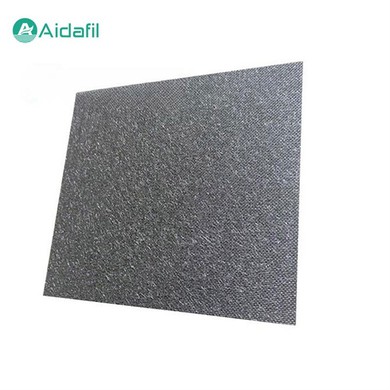

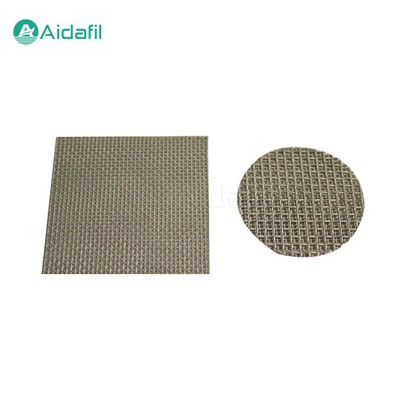

The stainless steel metal fiber sintered felt is a filter material made of stainless steel fiber wire through sintering process. It has good corrosion resistance, high temperature stability and efficient filtration effect, and is often used in the filtration of various liquids and gases to remove impurities and particles.

The production process of this sintered felt usually includes: combing stainless steel fiber filaments to form a fiber layer, and then sintering at high temperature to make the fiber filaments fuse together to form a porous felt structure with certain mechanical strength. According to needs, the sintered felt can be made into different thicknesses, densities and sizes to adapt to different filtering scenarios and precision requirements.

Features

1. Corrosion resistance

2. High temperature resistance

3. High strength

4. High filtration accuracy

5. Easy to clean and regenerate

6. Long life

7. Chemical stability

8. Good air permeability and dirt holding capacity

Range of use

Due to its unique physical and chemical properties, the stainless steel metal fiber sintered felt has a wide range of uses, including the following aspects:

1. Catalyst recovery

In the chemical production process, the stainless steel metal fiber sintered felt can be used for catalyst recovery, improving catalyst utilization and reducing waste emissions.

2. Hydraulic system filtration

In the fields of aviation, shipping, aerospace, etc., the stainless steel metal fiber sintered felt is used for filtration of hydraulic systems to ensure the cleanliness of hydraulic oil, thus maintaining the normal operation of the system.

3. Acid-base and corrosive media filtration

The stainless steel metal fiber sintered felt has strong corrosion resistance and is suitable for filtration of acid-base environments and corrosive media, such as chemical raw materials, pickling liquids, etc.

4. High temperature gas filtration

The stainless steel metal fiber sintered felt with high temperature resistance can be used for filtration and purification of high-temperature flue gas and industrial waste gas.

5. Metal melt filtration

In the foundry industry, the stainless steel metal fiber sintered felt can be used to filter inclusions in molten metal and improve the quality of castings.

6. Water treatment

In the field of environmental protection, the stainless steel metal fiber sintered felt can be used for the pretreatment of industrial wastewater and domestic wastewater to remove suspended solids and harmful particles from the water.

7. Food and beverage filtration

In the food and beverage industry, the stainless steel metal fiber sintered felt is used to filter purified water, fruit juices, alcohol, and other liquids to ensure the quality and safety of products.

8. Pharmaceutical industry

In the pharmaceutical process, the stainless steel metal fiber sintered felt is used to filter pharmaceutical solutions to ensure the purity and safety of medicines.

9. Other industrial applications

For example, in the automotive manufacturing, oil and gas extraction and processing, textile printing and dyeing industries, the stainless steel metal fiber sintered felt is used.

Model parameters

|

Model |

Filter precision (μm) |

Bubbling point pressure (pa) |

Air permeability (L/min, dm2, kpa) |

Porosity (%) |

Containment capacity (mg/cm2) |

Thickness (mm) |

Fracture strength (Mpa) |

|

Basic value |

Basic value |

Basic value |

Basic value |

Basic value |

Basic value |

||

|

ADZB-5 |

5 |

6800 |

47 |

75 |

5 |

0.3 |

32 |

|

ADZB-7 |

7 |

5200 |

63 |

76 |

6.5 |

0.3 |

36 |

|

ADZB-10 |

10 |

3700 |

105 |

75 |

7.8 |

0.37 |

32 |

|

ADZB-15 |

15 |

2450 |

205 |

79 |

8.6 |

0.4 |

23 |

|

ADZB-20 |

20 |

1900 |

280 |

80 |

15.5 |

0.48 |

23 |

|

ADZB-25 |

25 |

1550 |

355 |

80 |

19 |

0.62 |

20 |

|

ADZB-30 |

30 |

1200 |

520 |

80 |

26 |

0.63 |

23 |

|

ADZB-40 |

40 |

950 |

670 |

78 |

29 |

0.68 |

26 |

|

ADZB-60 |

60 |

630 |

1300 |

85 |

36 |

0.62 |

28 |

|

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

What factors affect the filtration effect of stainless steel metal fiber sintered felt?

1. Pore size of sintered felt

The pore size directly affects the filtration accuracy. Larger pore sizes are suitable for filtering larger particles, while smaller pore sizes can filter finer substances.

2. Density of sintered felt

The higher density sintered felt has higher filtration efficiency, but may also result in lower flow rates; the lower density sintered felt allows for higher flow rates, but may reduce the ability to capture fine particles.

3. Thickness of sintered felt

The increase in thickness will improve the filtration effect, but may result in increased pressure loss and decreased flow rate; the opposite is true for thinner sintered felts.

4. Work pressure

The pressure during the filtration process directly affects the speed at which the fluid passes through the sintered felt. Too low pressure can lead to inefficient filtration, and too high pressure can damage the sintered felt.

5. Viscosity of fluid

The viscosity of the fluid can affect its speed through the sintered felt, and high-viscosity fluids can cause filtration to slow down.

6. Type and concentration of pollutants

Different types of contaminants may have different penetration rates for sintered felts, and the concentration of contaminants can also affect the filtration effect.

7. Use status of sintered felt

The increase in use time will cause the sintered felt to clog, which in turn affects the filtration effect; timely cleaning or replacement of the sintered felt can restore its filtration performance.

8. Preprocessing

For some specific contaminants, specific pretreatment steps may be required to improve the filtration effect on the sintered felt.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: stainless steel metal fiber sintered felt, China, factory, price, buy, industrial air compressor oil separator, long life span gas coalescing filter, Carbon Steel Bag Filter Housing, 3um compressed air coalescing filter, Air Oil Separator, natural gas dehydration filter elements