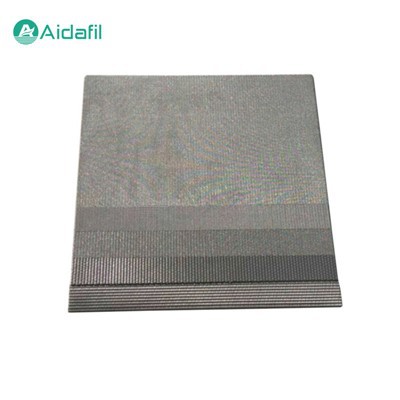

Three-Dimensional Mesh Titanium Fiber Sintered Felt

Product Details

The three-dimensional mesh titanium fiber sintered felt is a high-performance filter material made of tiny titanium fibers through a special process. It is a three-dimensional mesh, porous structure material made of micron-sized titanium fibers through a special laying process and high-temperature vacuum sintering process. It has high porosity, large surface area, uniform pore size distribution, and good pressure resistance and corrosion resistance. This material can be folded and bent and is suitable for various industries, such as PEM pure water electrolysis hydrogen production, civil use, medical care, etc.

Characteristics of three-dimensional mesh titanium fiber sintered felt

1. Physical structure:

- High porosity: Sintered felt has a porosity of more than 95%, which gives it a large specific surface area and good permeability.

- Three-dimensional mesh structure: The three-dimensional structure composed of fine fibers ensures the stability and compressive resistance of the material.

2. Chemical properties:

- Good chemical stability: Titanium fiber has excellent corrosion resistance to many acids, alkalis and organic solvents.

- Antioxidation: It has good antioxidant capacity at high temperatures and can be used for a long time in harsh environments.

3. Filtration performance:

- High-efficiency filtration: Due to its unique microstructure, titanium fiber sintered felt can effectively filter out fine particles.

- Easy to clean: The material can be cleaned repeatedly, is not easy to clog, and has a long service life.

Parameters of three-dimensional mesh titanium fiber sintered felt

|

High porosity |

60-70% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

|

Low porosity |

50-60% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

Application of three-dimensional mesh titanium fiber sintered felt

1. Industrial filtration:

- Water treatment: used to remove suspended matter, microorganisms and other harmful substances in water.

- Chemical industry: used to filter chemicals and catalysts in chemical production.

2. Energy:

- Nuclear energy: used to isolate radioactive materials in nuclear fuel processing and post-processing.

- New energy vehicles: used as gas diffusion layers in fuel cell systems.

3. Healthcare:

- Biomedical materials: due to their good biocompatibility, they can be used to manufacture medical devices implanted in the body.

- Drug carriers: using their porosity, they can be used as carriers for drug sustained-release systems.

Advantages of three-dimensional mesh titanium fiber sintered felt

1. High cost-effectiveness:

- Compared with some imported products, titanium fiber sintered felt is more affordable and has the same excellent performance.

- Products of different specifications can be customized according to customer needs to meet diverse needs.

2. Environmental protection:

- Titanium fiber sintered felt has little impact on the environment during production and use, which is in line with the trend of green manufacturing.

Manufacturing process

The manufacturing process of the three-dimensional mesh titanium fiber sintered felt is mainly divided into two steps: preparation and sintering of titanium fibers.

1. Preparation of titanium fiber

- Raw material selection: High-purity titanium powder is usually used as raw material, which is prepared by atomization or electrolysis.

- Fiber formation: Titanium powder is converted into filaments by mechanical or chemical methods, and then micron-sized titanium fibers are obtained by wire drawing technology.

2. Sintering

- Laying: The prepared titanium fibers are evenly laid into one or more layers to form the desired felt structure.

- Vacuum sintering: The laid fiber felt is placed in a vacuum sintering furnace to connect the titanium fibers to each other at high temperature to form a strong three-dimensional mesh structure. During this process, temperature and pressure need to be strictly controlled to ensure the porosity and mechanical strength of the final product.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: three-dimensional mesh titanium fiber sintered felt, China, factory, price, buy, cartridge compressed air coalescing filter, Sintered Metal Filter Disc, self cleaning screen filter without shutdown, 0 1 um separator filter, coalescing filter cartridge for artificial gas, hydraulic filter gas filter element