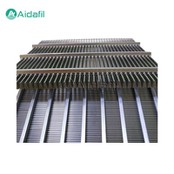

High Porosity Titanium Powder Sintered Filter Material

Product Details

The high porosity titanium powder sintered filter material is a kind of high-efficiency porous filter material made of industrial high-purity titanium powder (99.4%) through powder classification, molding, sintering, mechanical welding and other processes. Its internal pores are curved and crisscrossed, the pore size distribution is uniform, and the filtration mechanism is a typical deep filtration.

The high porosity titanium powder sintered filter material, it is widely used in the fields of pharmaceutical industry, water treatment industry, food industry, bioengineering, chemical industry, petrochemical industry, metallurgical industry and gas purification.

Properties

The high porosity titanium powder sintered filter material has the following excellent properties:

1. Uniform pore size and stable pore shape

The pore size of titanium powder sintered filter material is uniform and the pore shape is stable, which can ensure the accuracy and efficiency of filtration.

2. High porosity and small filtration resistance

Its high porosity and small filtration resistance can improve the filtration speed and flux.

3. High temperature resistance and good chemical stability

This material has good high temperature resistance and can be used normally below 250°C. It also has excellent chemical stability, acid and alkali corrosion resistance, and strong antioxidant properties.

4. No particle shedding, in line with food hygiene and pharmaceutical GMP requirements

No particles will fall off during use, and no secondary pollution will be caused to the original liquid, which meets the requirements of food hygiene and pharmaceutical GMP.

5. Good mechanical properties, low pressure difference, large flow rate

It has good mechanical properties, low pressure difference, large flow rate, can be pressed and filtered, and is easy to operate.

6. Strong antimicrobial ability

The titanium powder sintered filter material has antimicrobial ability and does not react with microorganisms.

7. Online regeneration, easy to clean, long service life

The material can be regenerated online, easy to clean, and has a long service life, which is generally several times that of a membrane filter element.

Parameters

|

Value of particles blocked in liquid |

Permeability (no less than) |

|||

|

Filtration efficiency (98%) |

Filtration efficiency (99.9%) |

Permeability (10-12m2) |

Relative permeability |

MPa |

|

1 |

3 |

0.05 |

5 |

3 |

|

3 |

5 |

0.08 |

8 |

3 |

|

5 |

10 |

0.3 |

30 |

3 |

|

10 |

14 |

0.8 |

80 |

3 |

|

15 |

20 |

1.5 |

150 |

3 |

|

20 |

32 |

2 |

200 |

3 |

|

35 |

52 |

4 |

400 |

2.5 |

|

60 |

85 |

6 |

600 |

2.5 |

|

80 |

124 |

10 |

1000 |

2.5 |

Application

The high porosity titanium powder sintered filter materials have good corrosion resistance, high temperature resistance, mechanical strength and filtration accuracy, and can be used in a variety of fields. The following are some situations where the high porosity titanium powder sintered filter materials may be needed:

1. Corrosive media filtration

In the chemical, pharmaceutical, petroleum and other industries, it is often necessary to filter corrosive media such as acids, alkalis, salt solutions, etc. Titanium powder sintered filter materials have excellent corrosion resistance and can operate stably for a long time in these harsh environments.

2. High temperature environment filtration

Some industrial processes require filtration under high temperature conditions, such as catalytic cracking in petrochemicals, high temperature flue gas filtration in steel production, etc. Titanium powder sintered filter materials can withstand high temperatures and can ensure the filtration effect and normal operation of equipment.

3. Food and pharmaceutical industries

In food and pharmaceutical production, the requirements for filter materials are very strict, and it is necessary to ensure that no harmful substances are introduced and no pollution is caused to the product. Titanium powder sintered filter materials have good chemical stability and biocompatibility, which meet the requirements of the food and pharmaceutical industries.

4. Gas purification

In the field of gas purification, such as air purification, industrial waste gas treatment, etc., it is necessary to remove impurities and particulate matter from the gas. Titanium powder sintered filter materials can effectively filter tiny particles and improve gas quality.

5. High-precision filtration

For some occasions with high requirements for filtration accuracy, such as the electronics industry and semiconductor manufacturing, the pore size distribution of titanium powder sintered filter materials is uniform and can meet the needs of high-precision filtration.

6. Other fields

Titanium powder sintered filter materials can also be used in water treatment, aerospace, nuclear industry and other fields. In these fields, the performance requirements for materials are also very high, and the excellent performance of titanium powder sintered filter materials makes it an ideal choice.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: high porosity titanium powder sintered filter material, China, factory, price, buy, durable gas coalescing filter, oil coalescing filter for steel plant, multi layer sintered wire mesh, Coalescer Filter Cartridge, Sintered Filter Disc, compact stainless steel duplex strainer