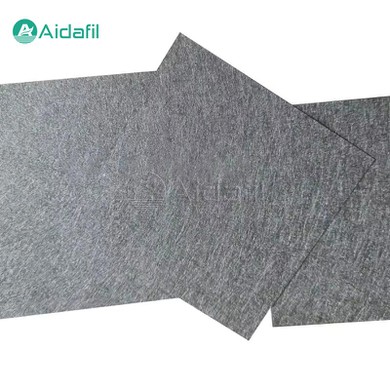

Excellent Industrial Filtration Material Titanium Fiber Sintered Felt

Product Details

The Excellent Industrial Filtration Material Titanium Fiber Sintered Felt is made of titanium fiber through a special process into a porous structure. It not only has the excellent properties of titanium materials, such as high strength, corrosion resistance and good heat resistance, but also has a large surface area and excellent air permeability due to its unique porous structure. These characteristics make titanium fiber sintered felt widely used in fields such as filtration, separation and catalyst carrier.

Physical and chemical properties

The physical properties of Excellent Industrial Filtration Material Titanium Fiber Sintered Felt are mainly affected by its microstructure and material. The material has a high porosity, usually up to about 70%, which means that there are a large number of micropores per unit volume, which can provide a wide range of channels for fluids. Such a structure not only ensures good air permeability, but also provides a large surface area, which is suitable for efficient material separation and chemical reactions. At the same time, the diameter of titanium fiber is usually at the micron or even submicron level, which makes the felt material have a higher surface area to volume ratio. This tiny fiber diameter and high surface area provide abundant active sites for catalytic reactions.

In terms of chemical properties, titanium, as a stable metal element, gives sintered felt excellent corrosion resistance. Titanium can remain stable in many highly corrosive environments, such as oxidative environments at high temperatures, environments containing chloride ions, etc. In addition, the titanium oxide layer formed during the sintering process further enhances the surface stability and corrosion resistance of the material. In terms of chemical treatment, titanium fiber sintered felt can be surface modified to improve its performance in specific applications, such as enhancing conductivity and chemical resistance through precious metal plating, or adjusting its application effect in liquid and gas phases through hydrophobic and hydrophilic coatings.

Parameters

|

High porosity |

60-70% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

|

Low porosity |

50-60% |

|

Thickness |

0.25, 0.40, 0.6, 0.8mm |

|

Average diameter equivalent |

30-60μm |

|

Size |

5x5 cm, 10x10 cm and 20x20 cm It can be customized. |

Application fields

The Excellent Industrial Filtration Material Titanium Fiber Sintered Felt has a wide range of applications, mainly due to its excellent physical and chemical properties.

In the field of environmental protection, it is used as a material for smoke filtration and wastewater treatment. Its high porosity and good corrosion resistance enable the capture of solid particles and droplets in high-temperature or corrosive exhaust gases, thereby effectively controlling factory emissions and protecting the environment.

In the medical field, titanium fiber sintered felt is often used to manufacture artificial bones and dental implants due to its superior biocompatibility and mechanical properties. Its porous structure allows the growth of soft tissue and bone cells, which helps the fixation and integration of implants. In addition, titanium fiber sintered felt is also used to manufacture filtration systems for medical devices to ensure the purity of gases and liquids used in surgery.

In the energy field, especially in hydrogen energy and fuel cell technology, titanium fiber sintered felt plays an important role as one of the key components. It is not only used to construct the gas diffusion layer of the electrode, promote the uniform distribution of the reaction gas, but also participates in the management of the heat and water balance inside the battery. These applications take advantage of the high electrical conductivity, good thermal stability and excellent chemical durability of titanium fiber sintered felt.

Production process

The production of the Excellent Industrial Filtration Material Titanium Fiber Sintered Felt involves several delicate steps. The first is the preparation process of titanium fiber. The original titanium wire needs to undergo a series of stretching processes to reach a predetermined micron-level diameter. These fibers are then laid through specific equipment to form a fiber mesh with a preliminary shape. In this step, the arrangement, density and uniformity of the fibers have an important influence on the performance of the final product.

The laid titanium fiber mesh will then undergo a sintering process. At this stage, the fiber mesh is placed in a high-temperature vacuum furnace, where the contact points between the fibers are fused by high temperature to form a stable three-dimensional network structure. Precise control of sintering temperature and time is essential to ensure the mechanical strength and optimization of the pore structure of the product. The details of this link directly affect the porosity, strength and overall performance of the felt.

In order to adapt to specific application requirements, titanium fiber sintered felt often requires further surface treatment. These include the application of hydrophobic and hydrophilic coatings, which change the wettability of its surface by adding specific functional groups or coatings. For example, in fuel cells, optimized hydrophobic treatment can help the gas diffusion layer manage moisture more effectively and improve the performance and life of the battery.

Why Choose Us

· Professional manufacturer with many years' experience

· Good quality with competitive price

· OEM & ODM are welcome

· Various payment items are acceptable

· Good service by experienced manager

AIDA Philosophy

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

· Focus on customer needs, provide best filtering solution

· To be the lifelong partner with customers

3. Corporate Vision:

· Become a global purification leadership brand

4. Values:

· Customer: Pursue the ultimate experience, enjoy excellent quality

· Team: Trust, responsibility, growth, win-win

· Work: Simple, sincere, efficient, dedicated

Hot Tags: excellent industrial filtration material titanium fiber sintered felt, China, factory, price, buy, 50 m self cleaning screen filter, superior glass fiber air compressor oil separator, composite materials coalescer filter cartridge, high quality ford oil filter element, oil separator to intercept impurities, automatic self cleaning filter against bacteria